What's Happening?

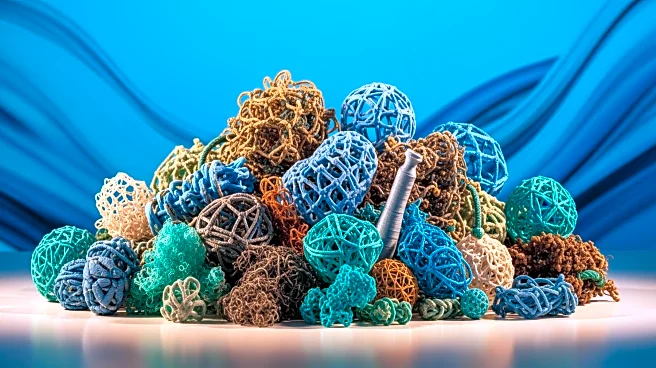

Scientists at the Indian Institute of Science (IISc) in Bengaluru have developed a method to recycle fishing nets made from Nylon 66 into 3D-printed products. The process involves using a chemical cross-linker,

melamine, to break down the polymer waste and rebuild it through transamidation, a rapid chemical reaction. This method, which takes less than two minutes, can be integrated into existing industrial recycling systems. The recycled nylon retains its strength and durability, making it suitable for manufacturing rigid products like park benches and pavement tiles. The startup VOiLA3D has already utilized this recycled material to produce various items, including furniture and a small speedboat.

Why It's Important?

This innovation addresses the environmental challenge posed by abandoned fishing nets, which harm marine ecosystems. By converting these nets into valuable products, the method offers a sustainable solution to plastic waste management. Economically, it creates opportunities for coastal communities, potentially providing new livelihoods through recycling initiatives. The ability to recycle tough materials like Nylon 66 could lead to broader applications in other industries, promoting circular economy practices and reducing reliance on virgin plastics.

Beyond the Headlines

The recycling of fishing nets into 3D-printed products not only mitigates environmental impact but also highlights the potential for technological advancements in waste management. This approach could inspire further research into recycling other hard-to-process materials, contributing to global efforts in sustainability. The collaboration between academia and industry exemplifies how innovative solutions can be scaled to address pressing environmental issues.