What's Happening?

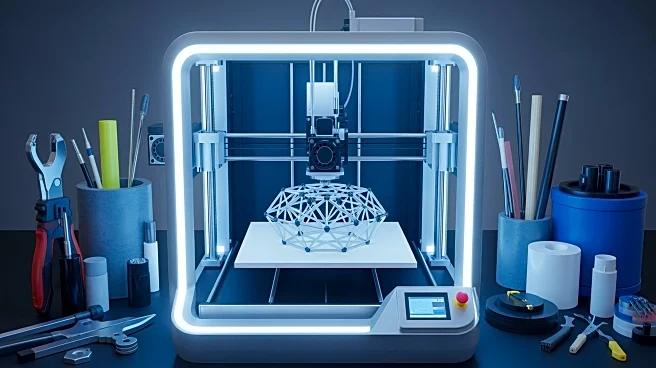

Additive manufacturing (AM) is transitioning from a backup plan to a baseline in modern production environments. This technology allows manufacturers to produce components directly from digital files,

eliminating the need for traditional tooling. Industries such as aerospace, automotive, and consumer electronics are adopting AM for faster iterations and lighter parts. The tool-less nature of AM enables manufacturers to experiment more and bring products to market with reduced lead times, solving supply chain bottlenecks and legacy part challenges.

Why It's Important?

The widespread adoption of additive manufacturing signifies a major shift in production methodologies, offering strategic advantages like reduced lead times and increased design flexibility. This transition is crucial for industries facing constant change and demand for innovation. By integrating AM, manufacturers can maintain competitiveness and adapt to evolving market needs. The technology also supports sustainability efforts by reducing material waste and enabling localized production, which could have long-term environmental benefits.

What's Next?

Manufacturers are likely to continue expanding their use of additive manufacturing, exploring hybrid approaches that combine AM with traditional methods for greater flexibility. As digital fluency and simulation capabilities improve, companies will be better equipped to implement AM effectively. The focus will be on mastering material families and leveraging simulation to reduce print failures and improve repeatability. Collaboration with technology providers experienced in hardware and software integration will be key to successful implementation.