What's Happening?

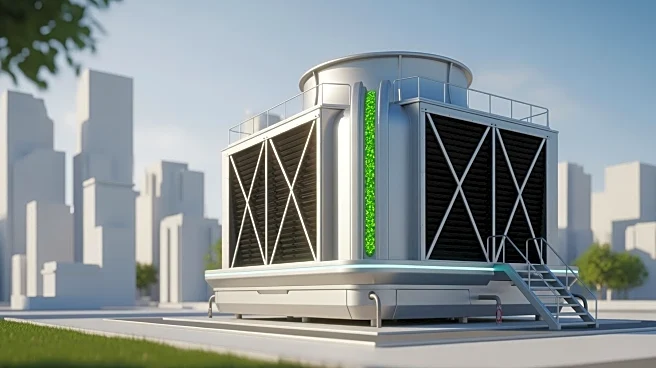

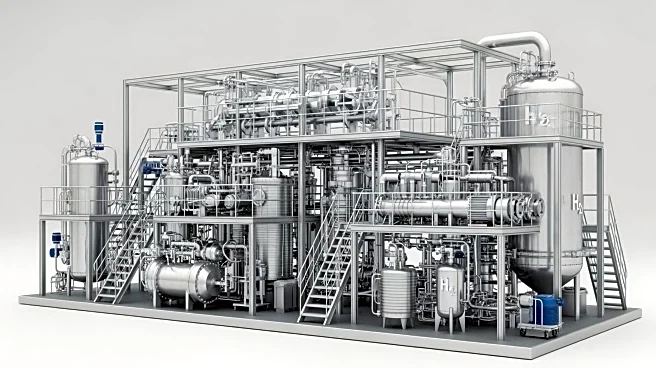

STMicroelectronics, in collaboration with SP Group, has initiated operations for Singapore's largest industrial district cooling system at its Ang Mo Kio TechnoPark. This system is designed to significantly enhance the environmental performance of STMicroelectronics'

semiconductor manufacturing site. The cooling system is expected to reduce carbon emissions by 120,000 tonnes annually and cut cooling-related electricity costs by 20 percent each year. Additionally, it will repurpose over half a million cubic meters of water annually. This marks STMicroelectronics' first use of district cooling at a manufacturing facility, reinforcing its commitment to achieving carbon neutrality by 2027.

Why It's Important?

The launch of this district cooling system is a significant step towards sustainable industrial practices, particularly in the semiconductor industry, which is known for its high energy consumption. By reducing carbon emissions and electricity costs, STMicroelectronics is setting a precedent for other companies in the sector to follow suit in adopting environmentally friendly technologies. This initiative not only supports Singapore's national sustainability goals but also aligns with global efforts to combat climate change. The project highlights the potential for collaborative innovation to transform urban infrastructure and deliver sustainable solutions.

What's Next?

STMicroelectronics plans to further its decarbonization efforts by upgrading the cooling system at its Toa Payoh site, with completion expected by December 2025. This upgrade aims to reduce carbon emissions by approximately 2,140 tonnes annually. The company is also implementing sustainable technologies across its campuses, including smart metering infrastructure to monitor energy consumption. These initiatives are part of a broader strategy to integrate digitalization and decarbonization at scale, contributing to a smarter, cleaner energy future.

Beyond the Headlines

The district cooling system not only reduces carbon emissions but also frees up space for additional environmental mitigation equipment, such as PFC abatement systems. This project achieved over 2 million accident-free man hours, underscoring the commitment to safety during construction. The cooling plant has been awarded the Green Mark Platinum Super Low Energy certification for its exceptional energy efficiency and sustainable design, further emphasizing the project's contribution to environmental stewardship.