What's Happening?

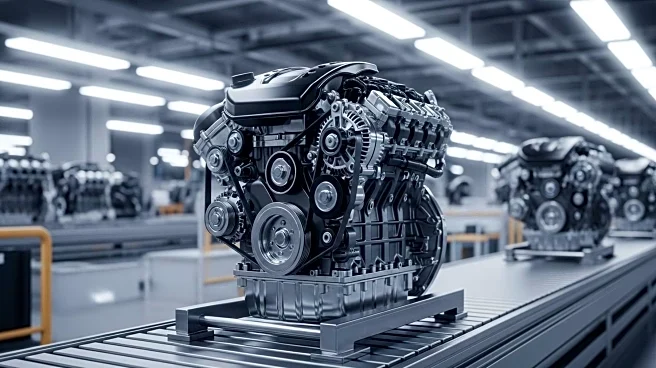

The renewed U.S.-China trade tensions are poised to disrupt auto supply chains, as manufacturers brace for potential impacts on production and logistics. Stellantis announced a $13 billion investment to add 5,000 U.S. factory jobs, supporting the production of

five vehicles and a new four-cylinder engine. This move comes amid concerns that escalating trade disputes could lead to increased tariffs and supply chain disruptions, affecting the availability of components and materials necessary for automotive manufacturing. The investment aims to bolster domestic production capabilities and mitigate potential risks associated with international trade uncertainties.

Why It's Important?

The automotive industry is highly sensitive to global trade dynamics, with supply chains spanning multiple countries. The renewed trade tensions between the U.S. and China could lead to increased costs and logistical challenges for automakers, potentially impacting production schedules and profitability. Stellantis' investment in U.S. manufacturing reflects a strategic effort to strengthen domestic capabilities and reduce reliance on international supply chains. This development highlights the broader industry trend of reshoring production to mitigate risks associated with geopolitical uncertainties and ensure continuity in manufacturing operations.

What's Next?

Automakers may need to explore alternative sourcing strategies and invest in domestic production facilities to safeguard against potential trade disruptions. The industry could witness increased collaboration between manufacturers and suppliers to enhance supply chain resilience and adaptability. As trade tensions evolve, stakeholders will likely monitor policy developments and adjust their strategies accordingly to navigate the complex landscape of international trade. The focus on domestic investment and production may also drive innovation in manufacturing processes and technologies, contributing to the industry's long-term sustainability.