What's Happening?

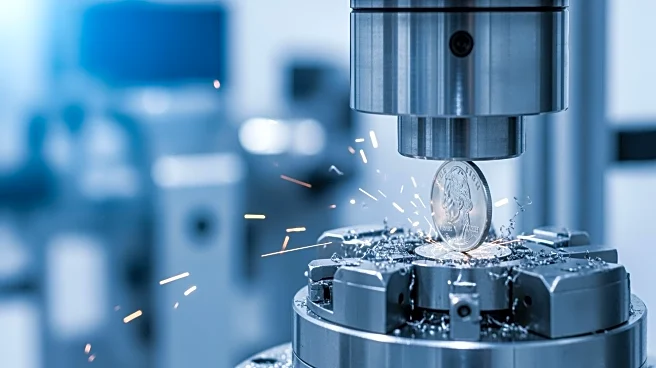

Sixpenny Additive, a newly established Canadian company specializing in metal additive manufacturing, has been appointed as the first distributor and integration partner for Meltio's wire-laser metal 3D printing systems in Canada. Meltio's technology,

known for its wire-laser directed energy deposition (DED), allows manufacturers to create fully dense metal parts using cost-effective welding wire. This technology can be integrated with robotic arms or function as standalone 3D printers, offering a combination of reliability, affordability, and scalability. Through this partnership, Sixpenny Additive will provide Canadian manufacturers with system sales and integration, local technical support, application development, and direct access to Meltio's printing services. David Nolan, president of Sixpenny Additive, expressed enthusiasm about introducing Meltio's technology to Canada, highlighting its potential to reduce costs and lead times for manufacturers.

Why It's Important?

The partnership between Sixpenny Additive and Meltio is significant for the Canadian manufacturing sector, as it introduces advanced metal 3D printing technology that can enhance production capabilities. This development is particularly relevant for industries such as automotive and aerospace, which require reliable and cost-effective solutions for producing complex metal parts. By offering local expertise and support, Sixpenny Additive aims to facilitate the adoption of this technology, potentially leading to increased competitiveness and innovation within Canadian manufacturing. The ability to produce parts that were previously uneconomical or impossible with traditional methods could drive significant advancements in product development and manufacturing efficiency.

What's Next?

As Sixpenny Additive begins its role as Meltio's distributor in Canada, the focus will likely be on building relationships with key industry players and demonstrating the benefits of wire-laser DED technology. The company may also work on expanding its service offerings and enhancing its technical support capabilities to ensure seamless integration for its clients. Additionally, the partnership could lead to further collaborations and innovations in the field of metal additive manufacturing, potentially influencing other markets and industries beyond Canada.

Beyond the Headlines

The introduction of Meltio's technology in Canada could have broader implications for the global manufacturing landscape. As more companies adopt advanced 3D printing solutions, there may be shifts in supply chain dynamics, with a potential reduction in reliance on traditional manufacturing processes. This could lead to more localized production, reducing transportation costs and environmental impact. Furthermore, the ability to rapidly prototype and produce parts could accelerate innovation cycles, allowing companies to bring new products to market more quickly.