What's Happening?

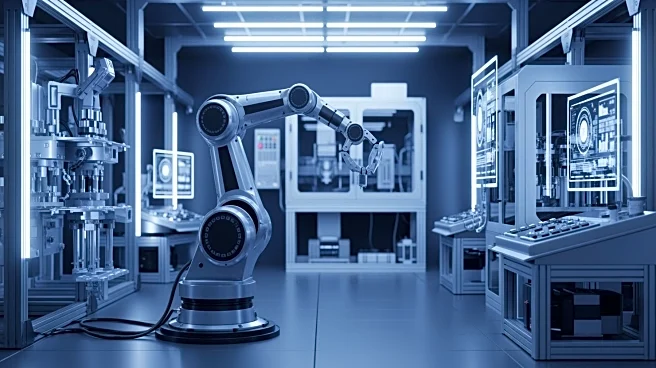

GrayMatter Robotics has inaugurated a new 100,000-square-foot headquarters and innovation center in Carson, California. This facility is designed to be the nation's most advanced interactive robotics experience

center for AI-powered manufacturing automation. The company aims to bring advanced manufacturing back to American soil, particularly in the South Bay region, leveraging its proximity to aerospace, marine, and other manufacturing clusters. The center will create over 100 jobs in engineering, AI and machine learning development, robotics integration, and operations, with potential for hundreds more as the company scales. GrayMatter Robotics provides physics-informed, AI-driven robotic cells to assist manufacturers with complex surface-finishing tasks, such as sanding, grinding, and polishing. The facility addresses challenges in automating surface finishing in high-mix production environments, where products vary constantly.

Why It's Important?

The opening of GrayMatter Robotics' innovation center is significant for the U.S. manufacturing industry, which has faced challenges in automating complex tasks due to variability in production environments. By reducing reliance on manual labor and offering faster, more efficient operations, GrayMatter's technology can enhance productivity and quality in manufacturing. This development is poised to revitalize American manufacturing, particularly in regions like Southern California, which have a rich history in aerospace and marine manufacturing. The facility's focus on AI-driven automation solutions could lead to increased competitiveness for U.S. manufacturers, potentially reversing decades of manufacturing decline. Additionally, the creation of new jobs and partnerships with local schools for robotics and AI training programs could foster a skilled workforce, further supporting the industry's growth.

What's Next?

GrayMatter Robotics plans to expand its physical AI applications beyond surface finishing, increasing its manufacturing capacity and customer base. The company intends to use the facility for workforce development initiatives, hosting student tours, technical workshops, and industry conferences to advance physical AI and intelligent manufacturing. As the company scales, it could add hundreds of skilled positions, demonstrating the viability of advanced manufacturing in Southern California. GrayMatter's 'factory-as-a-service' model, which eliminates upfront capital expenditures, aims to make advanced automation more accessible to small and midsize manufacturers, potentially transforming the manufacturing landscape in the U.S.

Beyond the Headlines

GrayMatter Robotics' approach to physical AI represents a shift from traditional industrial automation, focusing on AI that interacts with and manipulates the physical world through robotic systems. This technology must account for real-world variability, safety constraints, and continuous learning from physical interactions, offering a fundamentally different approach to manufacturing. The company's partnerships with industry leaders like FANUC and 3M highlight the collaborative efforts to enhance productivity and streamline operations. As physical AI becomes more integral to production, it could redefine manufacturing processes, making them more adaptable and efficient.