What is the story about?

What's Happening?

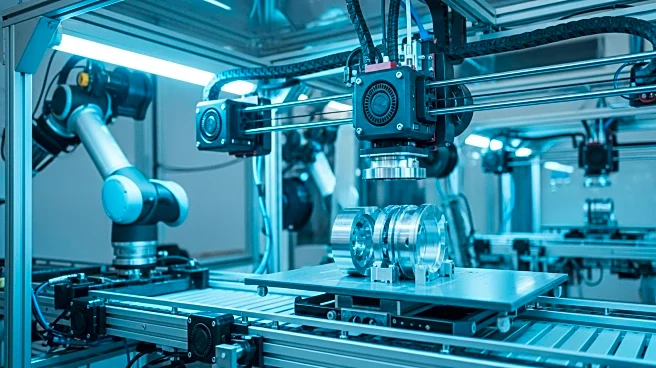

Eaton, a global industrial equipment company, has been integrating additive manufacturing technology across its operations, significantly impacting production efficiency. Cameron Peahl, manager for industry 4.0 and global AM strategy at Eaton, highlighted the importance of 3D printers in maintaining production lines. The company established the Additive Manufacturing Center of Excellence in Detroit in 2016, focusing on aerospace applications. This center has become a hub for industrializing aerospace production, experimenting with new techniques like cold spray and materials qualification. Eaton's approach to additive manufacturing is governed globally, ensuring efficient deployment across its 200 plants worldwide.

Why It's Important?

The integration of additive manufacturing at Eaton represents a significant shift in industrial production methods, offering potential cost savings and increased efficiency. By leveraging 3D printing, Eaton can quickly produce necessary tools and fixtures, reducing downtime and enhancing operational continuity. This approach not only supports Eaton's aerospace production but also sets a precedent for other industries to adopt similar technologies. The strategic use of additive manufacturing could lead to broader industry adoption, driving innovation and competitiveness in the U.S. manufacturing sector.

What's Next?

Eaton's continued investment in additive manufacturing suggests further advancements in production capabilities. As the company refines its techniques and expands its applications, other industries may follow suit, potentially leading to widespread adoption of 3D printing technologies. This could result in increased demand for skilled workers in additive manufacturing and further development of related technologies.

Beyond the Headlines

The ethical implications of additive manufacturing include potential job displacement due to automation. However, it also offers opportunities for workforce upskilling and innovation in manufacturing processes. Long-term, this technology could redefine production standards and sustainability practices within the industry.