What is the story about?

What's Happening?

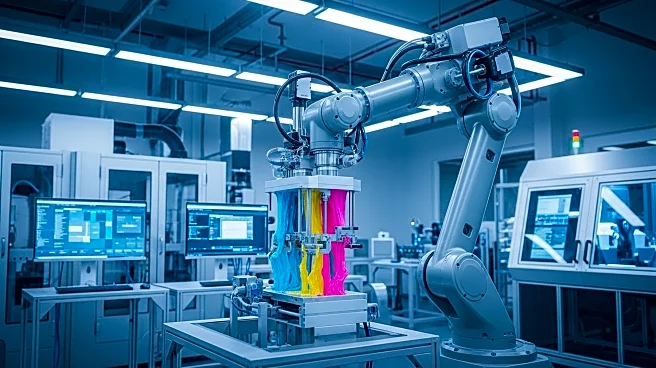

Premix, a company specializing in conductive polymer manufacturing, has significantly upgraded its production capabilities by integrating AI and automation technologies. The company's new facility in Charlotte is designed to minimize human intervention, utilizing advanced systems such as Allen Bradley PLCs and MachineView software to automate processes from raw material handling to finished goods. A key innovation is the PERTTI 3.0 platform, an in-house AI/ML system that transforms Premix's formulation database into a predictive tool, offering instant predictions of material properties and generating virtual formulations. The facility also employs Lean Six Sigma methodologies to foster continuous improvement, with operators trained as practitioners. Modern extruders and mixers equipped with real-time sensing capabilities ensure consistency in production by monitoring critical parameters.

Why It's Important?

The integration of AI and automation in Premix's manufacturing process represents a significant advancement in the polymer industry, potentially setting a new standard for efficiency and precision. By reducing manual handling and enhancing safety, the company can achieve more consistent and reproducible results, which is crucial for maintaining quality in large-scale production. This move could influence other manufacturers to adopt similar technologies, driving innovation and competitiveness in the U.S. manufacturing sector. Additionally, the use of AI for predictive modeling and formulation generation could lead to faster development cycles and cost savings, benefiting both the company and its clients.

What's Next?

As Premix continues to refine its automated processes, the company may explore further enhancements to its AI systems, potentially expanding their capabilities to include more complex predictive analytics and optimization features. The success of this facility could lead to similar implementations in other locations, broadening the impact of these technologies across the industry. Stakeholders, including equipment suppliers and engineering service providers, may also seek to collaborate on future projects, leveraging the insights gained from this initiative to drive further advancements in manufacturing technology.

Beyond the Headlines

The adoption of AI and automation in manufacturing raises important considerations regarding workforce dynamics. While these technologies can improve efficiency and safety, they may also lead to shifts in employment patterns, with a greater emphasis on technical skills and continuous learning. Companies like Premix will need to balance technological advancements with workforce development, ensuring that employees are equipped to thrive in increasingly automated environments. This shift could also prompt discussions on the ethical implications of automation, particularly in terms of job displacement and the need for reskilling programs.