What's Happening?

Researchers at the University of Illinois at Urbana-Champaign have developed a novel 3D printing technique that allows flat, 2D composite structures to morph into curved 3D forms once deployed in space.

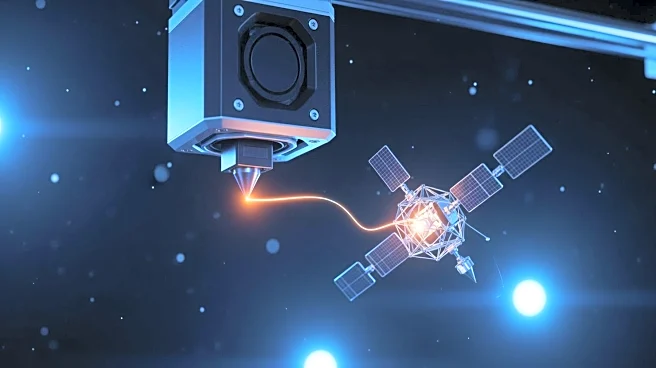

This advancement, led by aerospace Ph.D. student Ivan Wu and his advisor Jeff Baur, addresses previous limitations in low-energy morphing methods that resulted in insufficient stiffness for aerospace applications. The study, published in Additive Manufacturing, introduces a method that combines an energy-efficient resin system with a continuous carbon fiber 3D printer. This printer deposits carbon fiber bundles onto a print bed, which are then compressed and partially cured with ultraviolet light. The printed fiber architecture is embedded in a liquid resin and frozen. A low-energy thermal stimulus activates a chemical reaction that cures the resin, transforming the flat composite into a curved shape through a process called frontal polymerization.

Why It's Important?

This development is significant for the aerospace industry as it offers a scalable and energy-efficient method to create large space-based components without the need for large ovens or autoclaves. The ability to morph structures into desired shapes using a small thermal trigger could revolutionize the way deployable satellite antennas and other space structures are manufactured and deployed. The method's scalability and efficiency could lead to cost reductions and increased feasibility of complex space missions. Additionally, the technique's potential application in remote Earth environments suggests broader implications for engineering and construction in challenging settings.

What's Next?

The researchers propose using the morphed shapes as reusable molds to fabricate high-stiffness composites in orbit, addressing the current limitation of insufficient stiffness for direct structural use in space. This approach could lead to the development of more robust and durable space structures. Further research and development are likely needed to refine the technique and explore its full potential in both space and terrestrial applications. The aerospace industry and related sectors may closely monitor these advancements for potential integration into future projects.

Beyond the Headlines

The technique draws inspiration from the Japanese art of kirigami, achieving smooth curvature through controlled bending rather than folds. This cultural influence highlights the interdisciplinary nature of modern engineering innovations. The method's reliance on a low fiber volume fraction to balance flexibility with stiffness also underscores the ongoing challenge of optimizing material properties for specific applications. As the technology matures, it could lead to new standards in material science and engineering, influencing how structures are designed and manufactured across various industries.