What's Happening?

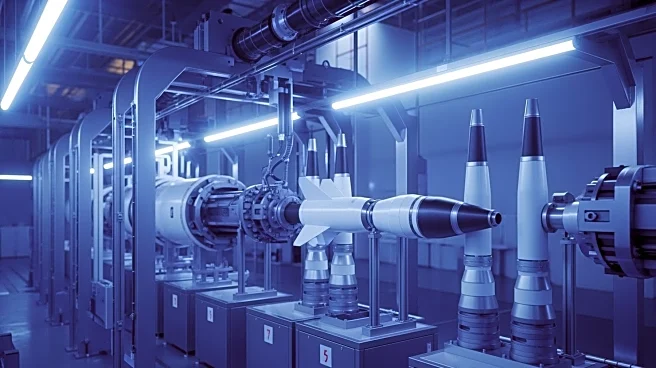

BAE Systems is enhancing its solid rocket motor (SRM) production capabilities at the Radford Army Ammunition Plant in Virginia. This expansion is part of a government-owned, contractor-operated framework

aimed at bolstering the production of tactical missiles. The plant employs the extrusion method, a technology that predates the more modern cast-and-cure systems. Joe Bellotte, research and development manager for BAE Systems Ordnance Systems, highlighted efforts to bridge the gap between these technologies, emphasizing the cost-effectiveness and high-volume production potential of the extrusion method. The expansion includes increasing the diameter of the SRMs produced and incorporating higher energy density materials.

Why It's Important?

The expansion of BAE Systems' production capabilities is significant for the U.S. defense industry, as it enhances the country's ability to produce tactical missiles more efficiently and affordably. This development could lead to increased readiness and deterrence capabilities for the U.S. military. By improving the energy density and production volume of SRMs, BAE Systems is positioning itself to meet the growing demand for advanced missile systems. This move could also have economic implications, potentially leading to job creation and increased economic activity in the region surrounding the Radford plant.

What's Next?

As BAE Systems continues to expand its production capabilities, it may seek further advancements in SRM technology to maintain its competitive edge. The company might also explore additional partnerships or contracts with the U.S. government to support its expanded production capacity. Stakeholders, including military leaders and policymakers, will likely monitor the impact of this expansion on national defense capabilities and the broader defense industry.