What's Happening?

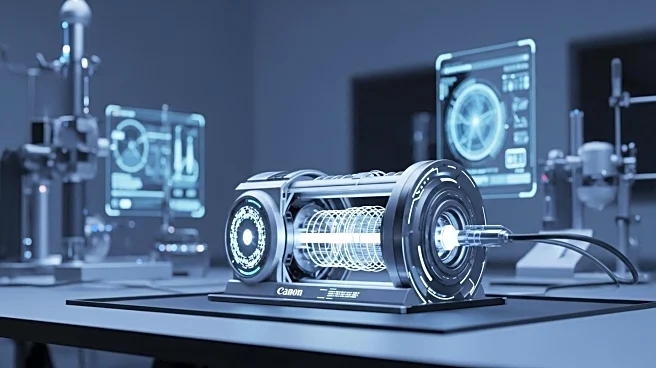

Babcock & Wilcox has unveiled its BrightLoop technology, a chemical looping process designed to convert diverse feedstocks into usable energy. This innovative process utilizes proprietary TranspO2rt particles, which are iron-oxide oxygen carriers, to enable conversion without combustion. The technology aims to enhance efficiency, reliability, and carbon separation, supporting energy diversity and independence. BrightLoop is applicable across various sectors, including power generation, manufacturing, and petrochemical industries, offering solutions for steam, hydrogen, or syngas production.

Why It's Important?

The introduction of BrightLoop technology is significant as it addresses the growing need for flexible and scalable energy solutions amidst global energy transitions. By providing a method for efficient energy conversion and inherent carbon separation, BrightLoop supports sustainability goals and energy independence. Industries such as power generation and manufacturing stand to benefit from improved reliability and efficiency, potentially reducing their carbon footprint and enhancing operational capabilities.

What's Next?

BrightLoop projects are designed to be standardized systems capable of processing a wide variety of feedstocks and operating at different scales. This scalability suggests potential expansion and adoption across various industries seeking sustainable energy solutions. As the technology gains traction, it may influence policy priorities and infrastructure development, aligning with global efforts to transition to cleaner energy sources.

Beyond the Headlines

The deployment of BrightLoop technology could have broader implications for the hydrogen economy and clean coal power production. By offering low-carbon hydrogen production and net-negative energy solutions, BrightLoop may contribute to reducing reliance on traditional steam methane reforming and promoting cleaner energy alternatives.