What's Happening?

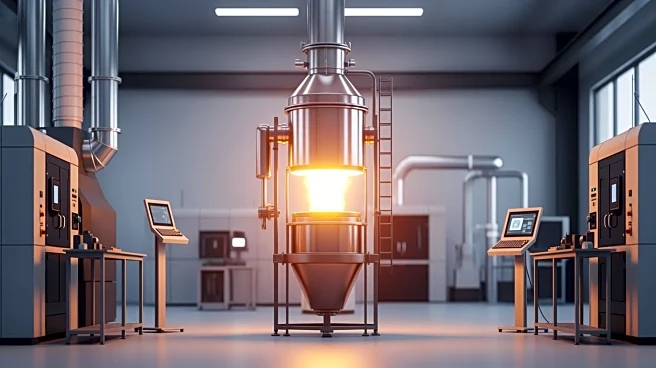

Adani Cement has implemented Coolbrook's RotoDynamic Heater (RDH) technology at its Boyareddypalli plant in Andhra Pradesh, marking the first commercial deployment of this system in the cement industry.

The RDH technology, powered by renewable energy, aims to decarbonize the calcination phase of cement production, which is highly fossil fuel-intensive. This deployment is expected to reduce carbon emissions by approximately 60,000 tonnes annually, with potential for a tenfold increase. The initiative aligns with Adani Cement's sustainability goals, including increasing alternative fuel usage and green power share.

Why It's Important?

The deployment of RDH technology represents a significant advancement in industrial decarbonization, particularly in the cement sector, which is a major contributor to global CO2 emissions. By utilizing clean heat, Adani Cement can significantly reduce its carbon footprint, supporting India's emergence as a leader in clean manufacturing. This move also sets a precedent for other industries to adopt similar technologies, potentially leading to widespread reductions in industrial emissions and progress towards global climate targets.

What's Next?

Adani Cement plans to expand the use of RDH technology across its operations, with ambitions to launch additional projects within the next two years. This expansion will further enhance the company's sustainability efforts, improving process efficiency and increasing the use of alternative fuels. As the technology proves its effectiveness, it may be adopted by other sectors, contributing to broader industrial decarbonization efforts.

Beyond the Headlines

The successful deployment of RDH technology highlights the potential for innovative solutions in reducing industrial emissions. It underscores the importance of collaboration between technology providers and industry leaders in achieving sustainability goals. This initiative also reflects the growing trend of integrating renewable energy sources into traditional manufacturing processes, paving the way for a more sustainable industrial future.