What's Happening?

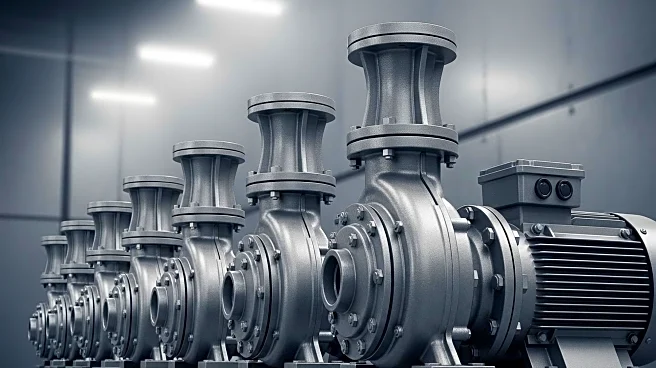

KSB GIW Inc has introduced the GIW LCC Gen2 slurry pump series, an upgraded version of its existing GIW LCC line. The new series is designed for class 1-3 slurry applications and incorporates improved hydraulic performance, streamlined maintenance, and extended service life. Key features include a front pull-out shaft seal design, threaded flanges, and zinc-plated fasteners, all aimed at enhancing serviceability and reliability. The pumps are available in three wet-end configurations, offering tailored solutions for different process conditions. Availability will roll out in phases across North America, with full availability expected by mid-summer 2026.

Why It's Important?

The launch of the GIW LCC Gen2 series represents a significant advancement in slurry pump technology, offering improved durability and reduced maintenance costs. This development is crucial for industries relying on slurry pumps, such as mining and construction, as it promises to lower operational costs and increase efficiency. The cross-compatibility of major parts between the Gen1 and Gen2 pumps further aids in reducing inventory costs and streamlining spare parts management. As the series becomes available globally, it is expected to enhance operational capabilities and support infrastructure development in various sectors.

What's Next?

KSB GIW plans to expand access to the GIW LCC Gen2 series worldwide, with rollout in all major markets expected before the end of next year. The company is working with its global supply chain to ensure fast access to parts, service, and inventory, which will be crucial for customers seeking to upgrade their equipment. As the series gains traction, it may lead to increased demand for slurry pumps with similar features, prompting further innovations in the industry.

Beyond the Headlines

The introduction of the GIW LCC Gen2 series highlights the importance of customer feedback in product development. By incorporating direct input from users, KSB GIW has created a pump that not only meets technical requirements but also addresses practical concerns related to maintenance and cost-efficiency. This approach may set a precedent for other companies in the industry, emphasizing the value of user-centric design in engineering durable and efficient equipment.