What's Happening?

AML3D, a wire arc additive manufacturing company based in Adelaide, has secured its largest contract to date with Newport News Shipbuilding, a subsidiary of HII, the USA's biggest shipbuilder. The contract,

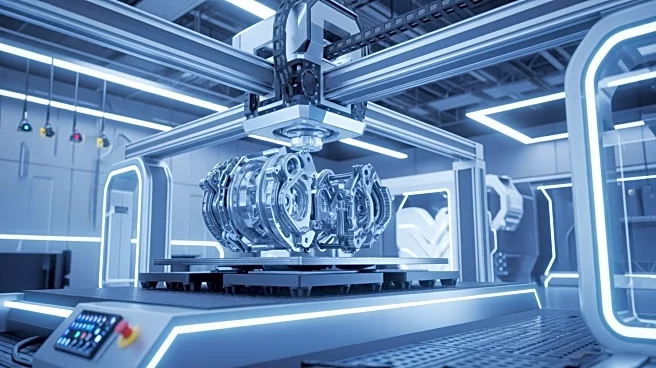

valued at approximately $4.5 million, involves the delivery of two custom-built Arcemy machines. These systems are designed to support the US Navy's Maritime Industrial Base and represent the ninth and tenth ARCEMY systems ordered for this purpose. The machines will be constructed using the large-format Arcemy X model, equipped with a 10,886kg positioner to enhance heavy capacity build capabilities. AML3D's technology, founded in 2014, utilizes robotic-controlled layer-by-layer building of welding beads to form near-net shapes. The company has recently expanded its presence in the US by opening a headquarters and factory in Ohio.

Why It's Important?

This contract marks a significant milestone for AML3D, reinforcing its position in the shipbuilding sector and expanding its footprint in the US defense market. The deployment of advanced manufacturing systems like the Arcemy machines is crucial for enhancing the capabilities of the US Navy's Maritime Industrial Base. As demand for such technology accelerates across the US and other international defense markets, AML3D's established manufacturing base in the US provides a strategic advantage, particularly in light of evolving US Government tariff policies. This development not only strengthens AML3D's market presence but also contributes to the modernization and efficiency of naval shipbuilding processes.

What's Next?

AML3D's expansion in the US market is likely to continue, with potential for further contracts and collaborations within the defense sector. The company's strategic positioning in Ohio and its growing reputation in additive manufacturing could lead to increased demand for its technology. As the US Navy and other defense entities seek to modernize their operations, AML3D's innovative solutions may play a pivotal role in future projects. Additionally, the company's ability to adapt to tariff changes and maintain competitive pricing could further enhance its appeal to US customers.

Beyond the Headlines

The integration of advanced manufacturing systems like those provided by AML3D could have broader implications for the shipbuilding industry, potentially leading to more sustainable and efficient production methods. The use of additive manufacturing technology may reduce material waste and energy consumption, aligning with global efforts to promote environmentally friendly industrial practices. Furthermore, AML3D's success in securing significant contracts may inspire other companies in the sector to invest in similar technologies, driving innovation and competition.