What's Happening?

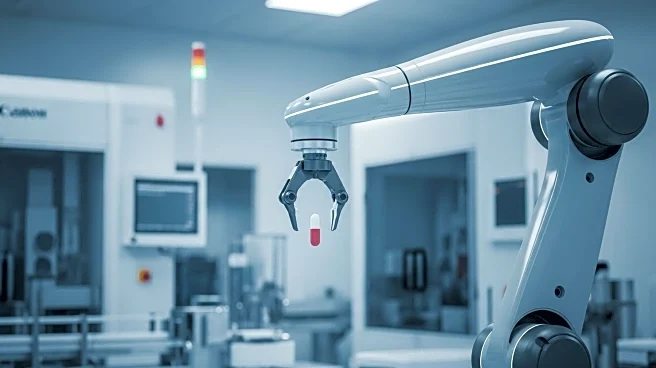

A global pharmaceutical company has integrated its lyophilizers with its SCADA system, enhancing production decision-making through automation upgrades. The integration involved upgrading the lyophilizer to a new platform, allowing data historization and standardized reporting across various systems, including single-use bioreactors and mixers. This move is part of the company's vision to standardize technologies for easier maintenance and improved operational efficiency.

Why It's Important?

The integration of lyophilizers with SCADA systems represents a significant advancement in pharmaceutical manufacturing. By standardizing technologies, the company can streamline operations, reduce maintenance complexity, and enhance data-driven decision-making. This approach not only improves production efficiency but also aligns with broader industry trends towards automation and digital transformation, potentially setting a precedent for other pharmaceutical companies.

What's Next?

The company may continue to explore further automation upgrades across its facilities, potentially expanding the integration to other systems and processes. This could lead to increased production capacity and efficiency, as well as improved compliance with industry standards. Stakeholders, including technology providers and regulatory bodies, may closely monitor these developments for potential impacts on industry practices.

Beyond the Headlines

The move towards automation and standardized technologies in pharmaceutical manufacturing raises ethical and legal considerations, particularly regarding data privacy and security. As companies increasingly rely on digital systems, ensuring robust cybersecurity measures and compliance with data protection regulations will be crucial.