What's Happening?

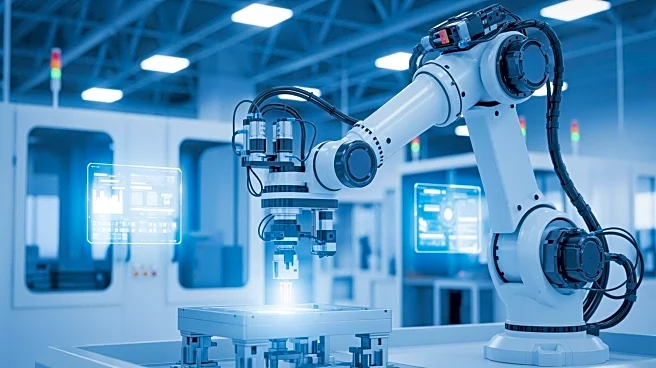

AgiBot, also known as Zhiyuan Robotics, has successfully deployed its Real-World Reinforcement Learning (RW-RL) system in a manufacturing pilot with Longcheer Technology. This system allows robots to learn

and adapt directly on the factory floor, significantly reducing training time and improving flexibility in precision manufacturing. The RW-RL system addresses challenges in traditional automation by enabling rapid deployment and high adaptability, maintaining industrial-grade stability and a 100% task completion rate. This development marks a new phase in intelligent automation for precision manufacturing.

Why It's Important?

The deployment of AgiBot's RW-RL system represents a major advancement in the field of robotics and AI, particularly in the manufacturing sector. By reducing training time and increasing adaptability, this system can significantly enhance efficiency and reduce costs in precision manufacturing. The ability to quickly reconfigure tasks and adapt to changes in production lines offers a competitive advantage in industries such as consumer electronics and automotive manufacturing. This innovation could lead to broader adoption of AI-driven solutions in manufacturing, transforming the industry and setting new standards for automation.

What's Next?

Following the successful pilot, AgiBot plans to expand the application of its RW-RL system to a wider range of manufacturing scenarios, including consumer electronics and automotive components. The company aims to develop modular, rapidly deployable robot solutions that integrate seamlessly with existing production systems. This expansion could further solidify AgiBot's position in the robotics industry and drive continued innovation in intelligent automation. The success of this system may also encourage other companies to explore similar AI-driven solutions, potentially leading to a shift in manufacturing practices globally.