What's Happening?

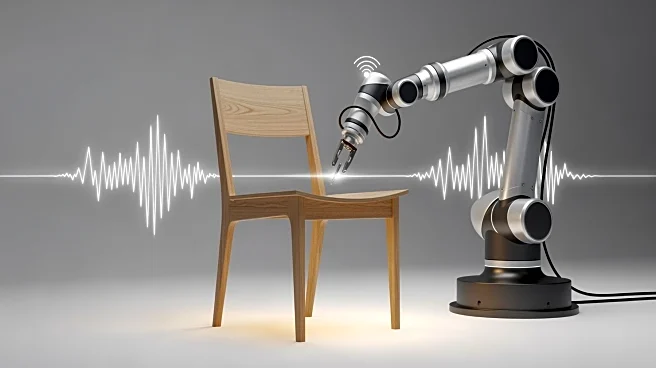

Researchers at the Massachusetts Institute of Technology (MIT) have unveiled a groundbreaking 'speech-to-reality' system that allows users to create physical objects, such as furniture, through simple voice commands. This innovative system integrates

natural language processing, 3D generative AI, and robotic assembly to transform spoken requests into tangible items. The project, led by graduate student Alexander Htet Kyaw, enables a robotic arm to construct objects like stools, shelves, and decorative items within minutes. The system begins with speech recognition, which processes the user's request using a large language model. It then employs 3D generative AI to create a digital mesh of the object, which is broken down into assembly components by a voxelization algorithm. The system's design aims to make manufacturing more accessible to those without expertise in 3D modeling or robotic programming.

Why It's Important?

This development represents a significant advancement in the field of AI and robotics, potentially revolutionizing the way physical objects are designed and manufactured. By enabling rapid assembly of objects from voice commands, the system could democratize access to manufacturing, allowing individuals and small businesses to create custom items without the need for extensive technical knowledge or expensive equipment. This could lead to increased innovation and personalization in product design, as well as reduced waste through the use of modular components that can be reassembled into different configurations. The system's ability to quickly produce items also offers potential applications in emergency situations or remote locations where traditional manufacturing resources are limited.

What's Next?

The MIT team plans to enhance the system's capabilities by improving the weight-bearing capacity of the furniture and exploring more robust connection methods for the modular components. They are also working on incorporating gesture recognition and augmented reality to further streamline the interaction between humans and robots in the fabrication process. These improvements could expand the system's applicability to larger and more complex structures, potentially transforming industries such as construction and interior design. The team's ongoing research aims to make the creation of physical objects faster, more accessible, and more sustainable, aligning with broader trends towards on-demand production and customization.