What's Happening?

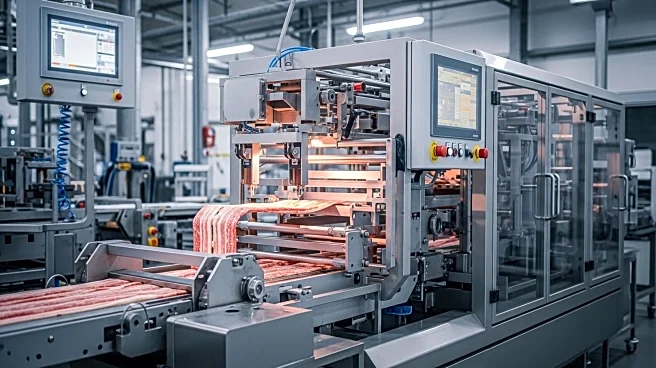

Middleby Food Processing, a leader in food service innovation based in Elgin, Illinois, has partnered with Rockwell Automation to develop the food industry's first fully automated bacon production line. This collaboration aims to address the growing demand for efficient, flexible, and sustainable food processing solutions. Rockwell Automation's expertise in engineering and seamless integration capabilities were pivotal in creating a unified automation platform that transforms production processes. The new system includes FactoryTalk Optix, which standardizes operator interfaces and application code libraries, enhancing production agility and enabling real-time data strategies. This development is part of Middleby's broader automation efforts across various food segments, including bakery and protein, designed to help customers manage rising labor costs, space constraints, and sustainability goals.

Why It's Important?

The introduction of a fully automated bacon production line marks a significant advancement in food manufacturing, potentially setting a new standard for efficiency and sustainability in the industry. By reducing labor and wastewater usage, this innovation could lead to cost savings and environmental benefits, making it attractive to food producers facing economic and regulatory pressures. The collaboration between Middleby and Rockwell highlights the importance of integrating advanced technology in food processing to remain competitive. This development could influence other companies to adopt similar automation strategies, potentially reshaping the food processing landscape and impacting labor markets and supply chains.