What is the story about?

What's Happening?

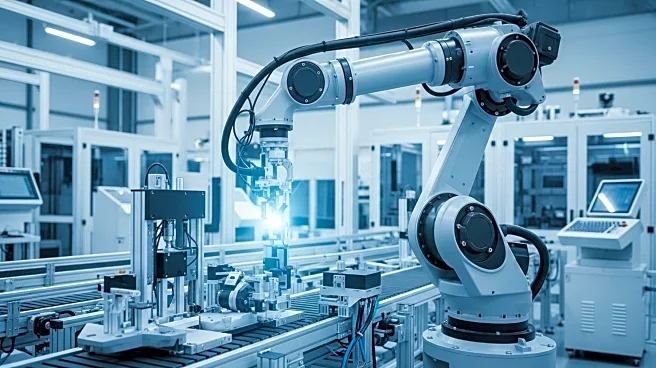

Industrial AI is emerging as a crucial tool for manufacturers aiming to localize their supply chains in response to global disruptions such as geopolitical tensions and trade tariffs. By leveraging AI, manufacturers can improve product design, remanufacturing, ESG reporting, and scenario planning. This shift from global to localized supply chains is driven by the need for greater flexibility, sustainability, and resilience. AI enables real-time simulations of supply chain disruptions, allowing manufacturers to make faster, smarter decisions and reduce reliance on single-source suppliers.

Why It's Important?

The adoption of Industrial AI for supply chain localization represents a significant shift in manufacturing strategies, with potential benefits including reduced lead times, lower transportation costs, and improved sustainability. By localizing supply chains, manufacturers can better manage risks associated with global disruptions and meet increasing regulatory demands for transparency and sustainability. This approach also supports the transition from 'just-in-time' to 'just-in-case' models, enhancing supply chain resilience and efficiency.

What's Next?

As more manufacturers adopt Industrial AI for supply chain localization, we can expect to see increased investment in AI technologies and a focus on developing local supplier networks. This trend may lead to greater collaboration between manufacturers and technology providers, as well as the development of new AI-driven tools and solutions. Additionally, the emphasis on sustainability and resilience could drive further regulatory changes, encouraging more companies to prioritize localized supply chains.