What's Happening?

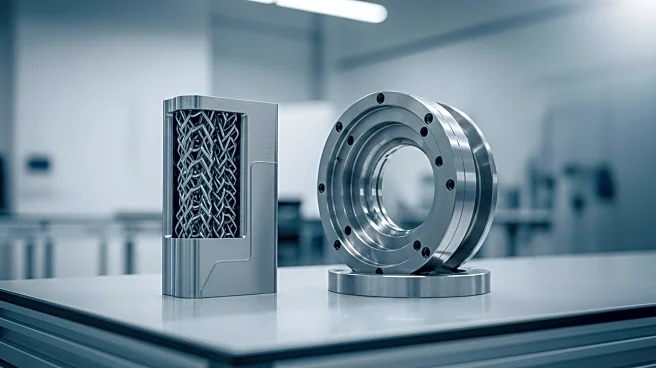

Titomic Ltd has announced a strategic partnership with Amaero Ltd to enhance its supply chain capabilities in the United States. This collaboration focuses on securing a consistent supply of high-quality spherical refractory and titanium alloy powders, which are essential for Titomic's cold spray additive manufacturing applications. The partnership aims to bolster Titomic's capabilities in coatings, repair, and near-net-shape part manufacturing, particularly for the defense and aerospace sectors. By aligning their efforts, both companies seek to provide reliable and advanced material solutions, positioning Titomic to better support its customers in these critical markets.

Why It's Important?

The partnership between Titomic and Amaero is significant for the U.S. defense and aerospace industries, which rely heavily on advanced manufacturing technologies. By securing a stable supply chain for essential materials, Titomic can enhance its manufacturing processes, potentially leading to more efficient production and improved product quality. This development is crucial as the U.S. continues to prioritize technological advancements in defense and aerospace, sectors that are vital for national security and economic growth. The collaboration also underscores the importance of resilient supply chains in maintaining competitive advantages in global markets.

What's Next?

As Titomic and Amaero move forward with their partnership, they are likely to focus on expanding their manufacturing capabilities and exploring new applications for their technologies. This could involve further investments in research and development to innovate and improve their product offerings. Additionally, the companies may seek to establish more partnerships or collaborations with other industry players to strengthen their market position. Stakeholders in the defense and aerospace sectors will be closely monitoring these developments, as they could lead to significant advancements in manufacturing technologies.

Beyond the Headlines

This partnership highlights the growing trend of collaboration between companies to address supply chain challenges and enhance technological capabilities. It also reflects the increasing importance of additive manufacturing in transforming traditional manufacturing processes, offering potential benefits such as reduced material waste and faster production times. As the industry evolves, ethical considerations around the environmental impact of manufacturing processes and the sustainability of supply chains may become more prominent.