What's Happening?

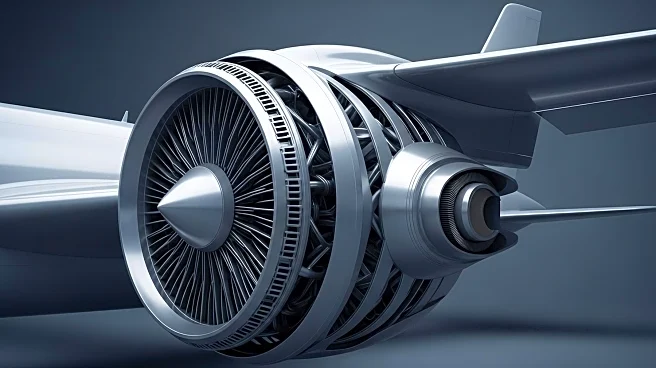

Spectrum Networks, LLC and ALOFT AeroArchitects are leveraging Markforged's additive manufacturing technology to produce certified, flight-ready components for VIP and government aircraft. This collaboration addresses the challenge of sourcing replacement parts during scheduled maintenance cycles, which can take aircraft out of service for extended periods. By using Markforged's FX10 platform and Continuous Fiber Reinforcement (CFR) technology, Spectrum Networks can design and manufacture replacement parts in weeks rather than months. These precision-engineered components are installed by ALOFT AeroArchitects, ensuring reliability for aircraft transporting world leaders and governments.

Why It's Important?

The use of Markforged's technology significantly reduces lead times for aircraft maintenance, enhancing operational readiness for fleets that serve critical roles. This advancement in additive manufacturing allows for rapid production of parts, minimizing downtime and ensuring the availability of aircraft for important missions. The collaboration between Spectrum Networks and ALOFT AeroArchitects demonstrates the potential of digital manufacturing to modernize supply chains and eliminate obsolescence, which is crucial for maintaining the efficiency and reliability of aerospace operations.

What's Next?

The ongoing partnership between Spectrum Networks and ALOFT AeroArchitects is expected to continue driving innovation in the aerospace sector. As more aircraft operators adopt additive manufacturing technologies, the industry may see a shift towards more sustainable and efficient production methods. The success of this collaboration could encourage other aerospace companies to explore similar technologies, potentially leading to broader acceptance and integration of additive manufacturing in aircraft maintenance and production.

Beyond the Headlines

The adoption of Markforged's technology by Spectrum Networks and ALOFT AeroArchitects highlights the growing importance of digital manufacturing in the aerospace industry. This shift not only improves efficiency but also supports sustainability initiatives by reducing waste and energy consumption associated with traditional manufacturing processes. The ability to produce parts on demand with high precision and traceability may also influence regulatory standards, paving the way for more widespread use of additive manufacturing in critical sectors.