What's Happening?

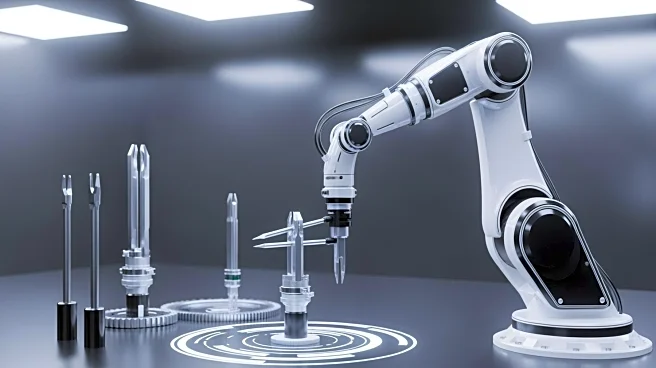

SK International, based in Wixom, Michigan, has announced the launch of its new division, SK Robotics, which was recently showcased at the 2025 Assembly Show in Rosemont, Illinois. The division focuses

on autonomous mobile robots (AMRs) and offers a range of products including a lidar series, a guided series, and an autonomous forklift series. These products are powered by DFleet and NavWiz AMR software. The lidar series features 12 models, while the guided and forklift series each include three models. The AMR fleet has reportedly achieved 300 deployments, and SK Robotics has also partnered with cobot maker Syntec Technology to enhance its offerings. The robots are designed with features such as payload capacities ranging from 300 kg to 2,000 kg, maximum speeds between 0.76 m/s and 1.6 m/s, and run times from 5 to 12 hours. They also include advanced navigation and safety systems.

Why It's Important?

The launch of SK Robotics signifies a significant advancement in industrial automation, potentially transforming productivity across various sectors. By integrating advanced robotics technology, industries can enhance efficiency, reduce labor costs, and improve safety in operations. The partnership with Syntec Technology further strengthens SK Robotics' position in the market, offering collaborative robots that can work alongside human workers. This development is crucial for industries looking to maintain competitiveness in a rapidly evolving technological landscape. The deployment of these robots can lead to increased output and streamlined operations, benefiting sectors such as manufacturing, logistics, and warehousing.

What's Next?

As SK Robotics continues to expand its product offerings and partnerships, the company is likely to see increased adoption of its AMR solutions across different industries. The focus on enhancing the capabilities of its robots through software and hardware innovations will be critical in meeting the diverse needs of industrial clients. Stakeholders in the manufacturing and logistics sectors may closely monitor the performance and integration of these robots to assess their impact on operational efficiency and cost savings. Additionally, the collaboration with Syntec Technology could lead to further advancements in cobot technology, potentially opening new markets and applications for SK Robotics.

Beyond the Headlines

The introduction of advanced robotics by SK International could have broader implications for the labor market, particularly in sectors heavily reliant on manual labor. While automation can lead to job displacement, it also creates opportunities for new roles focused on robot maintenance, programming, and system integration. The ethical considerations of automation, such as ensuring fair labor practices and addressing workforce transitions, will be important discussions as the industry evolves. Furthermore, the environmental impact of increased automation, including energy consumption and resource use, will need to be managed to ensure sustainable growth.