What's Happening?

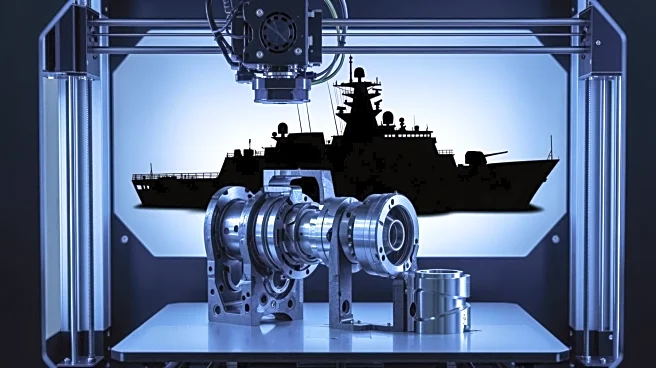

Stratasys participated in Trident Warrior 25, a U.S. Navy exercise demonstrating distributed manufacturing capabilities using 3D printing technology. The exercise involved field-deployable 3D printers and on-demand production, allowing the Navy to produce

parts in-theater or reach back to Stratasys Direct for complex production. This initiative aims to reduce downtime and maintain mission readiness by providing quick access to necessary components. The demonstration connected assets across more than 8,000 miles, showcasing the potential of additive manufacturing in military operations.

Why It's Important?

The use of 3D printing in military operations represents a significant advancement in logistics and maintenance, enhancing the U.S. military's ability to remain operational in challenging environments. By reducing reliance on traditional supply chains, the Navy can quickly produce parts and prototypes, improving resilience and readiness. This capability is crucial for maintaining the effectiveness of front-line vehicles and equipment, ensuring that military units can respond swiftly to emerging threats.

What's Next?

The success of Trident Warrior 25 may lead to further integration of 3D printing technology in military logistics and operations. The Navy and other branches of the military are likely to expand their use of additive manufacturing, exploring new applications and refining processes to enhance efficiency and effectiveness.

Beyond the Headlines

The adoption of 3D printing in military contexts raises questions about the future of manufacturing and supply chain management. As technology advances, the military may increasingly rely on distributed manufacturing, potentially transforming traditional logistics models and influencing broader industry practices.