What's Happening?

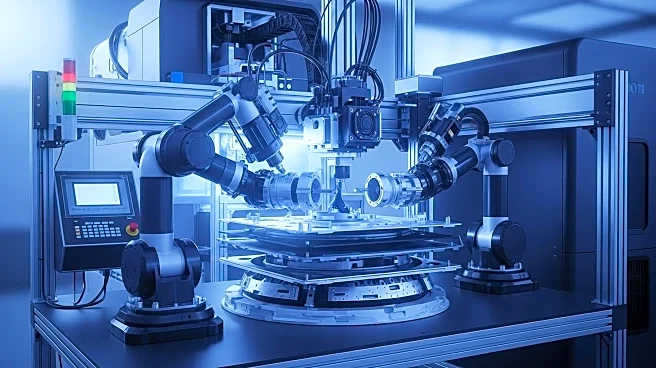

The U.S. Navy is scaling up its use of additive manufacturing, commonly known as 3D printing, to produce critical components for its Virginia-class and Columbia-class nuclear submarines. Lincoln Electric, a key player in U.S. Navy shipbuilding, is manufacturing these parts using large-scale wire arc additive manufacturing printers. This initiative aims to address supply chain bottlenecks by reducing lead times for essential components. Sponsored by the Navy's Maritime Industrial Base Program, Electric Boat will procure these parts, marking Lincoln's largest government-backed investment in additive manufacturing.

Why It's Important?

The adoption of additive manufacturing by the U.S. Navy represents a significant shift in military procurement strategies, emphasizing speed and quality over cost. This approach could revolutionize the defense industry's supply chain, enhancing the Navy's operational readiness and capability to respond to emerging threats. The initiative highlights the growing importance of advanced manufacturing technologies in national defense, potentially setting a precedent for other military branches and industries. The collaboration between Lincoln Electric and Electric Boat underscores the strategic importance of partnerships in advancing technological innovation.

What's Next?

As the U.S. Navy continues to integrate additive manufacturing into its production processes, further investments in technology and infrastructure are expected. The success of this initiative may lead to broader applications of 3D printing across other military platforms and industries. Stakeholders, including defense contractors and technology providers, will likely explore new opportunities for collaboration and innovation. The Navy's focus on reducing lead times and enhancing quality may drive further advancements in additive manufacturing techniques and materials.

Beyond the Headlines

The use of additive manufacturing in submarine production raises ethical and strategic considerations regarding the balance between cost efficiency and national security. The initiative may influence policy decisions related to defense spending and technological innovation. As the Navy leverages advanced manufacturing technologies, the potential for long-term shifts in defense procurement strategies and industry standards becomes apparent. The emphasis on rapid prototyping and complex part shapes reflects the evolving demands of modern warfare and the need for adaptable solutions.