What's Happening?

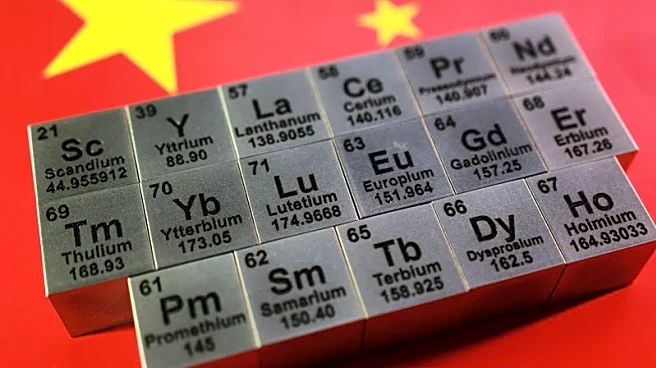

The automotive industry in the United States is experiencing significant challenges due to tariffs affecting the cost, availability, and sourcing of critical parts and raw materials. In 2023, the U.S. imported approximately 30,710 motor vehicles from Canada, a sharp decline from 58,090 the previous year. This reduction, while small compared to the 10.6 million vehicles produced domestically, could impact manufacturers like Stellantis. The industry relies on a global network of suppliers, with a substantial portion of components sourced from Mexico and Canada. Relocating production is costly and time-consuming, potentially leading to increased prices or financial losses for automakers.

Why It's Important?

The tariffs are reshaping the automotive sector's supply chain strategies, highlighting the vulnerability of global manufacturing networks. The increased costs and logistical challenges could lead to higher vehicle prices, affecting consumer affordability and demand. Manufacturers may need to reconsider their sourcing strategies, potentially leading to a shift towards regionalization. This situation underscores the broader economic implications of trade policies and their impact on industries reliant on international supply chains.

What's Next?

Automakers may need to explore alternative sourcing strategies or invest in domestic production capabilities to mitigate the impact of tariffs. This could involve significant capital investment and time, potentially affecting their competitive positioning. The industry might also see increased lobbying efforts for policy changes to alleviate tariff pressures.