What's Happening?

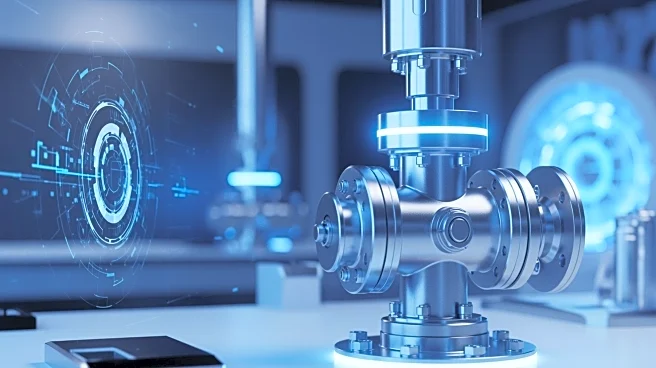

The Lee Company is addressing the limitations of traditional pyrotechnic valves used in defense systems. These valves, known for their single-use design and susceptibility to electromagnetic interference,

present challenges such as explosive shock, debris, and high lifecycle costs. Jim Gabinetti, Project Specialist at The Lee Company, discusses innovative alternatives like passive and non-passive valves. Passive valves operate without electrical input, relying on environmental triggers, while non-passive valves offer more control with electrical input. These alternatives aim to reduce risks associated with pyrovalves, such as foreign object debris and destructive testing, while providing improved operational capabilities.

Why It's Important?

The shift from pyrovalves to alternative valve solutions in defense systems could significantly impact the industry by reducing costs and enhancing reliability. Pyrovalves require stringent safety measures and are costly to qualify due to their explosive nature. The Lee Company's alternatives offer non-destructive testing and eliminate explosion-related safety concerns, potentially lowering operational overhead. This transition could benefit defense contractors by providing more durable and cost-effective solutions, improving mission reliability, and reducing lifecycle costs.

What's Next?

The Lee Company continues to work with defense contractors to replace pyrovalves with their innovative valve solutions. The replacement process often involves partial redesigns rather than complete system overhauls. The company assists customers in analyzing replacements and matching standard pyrovalve fitting connections. As the defense industry seeks to optimize performance and reduce risks, The Lee Company’s alternatives may become more widely adopted, influencing future defense system designs.