What's Happening?

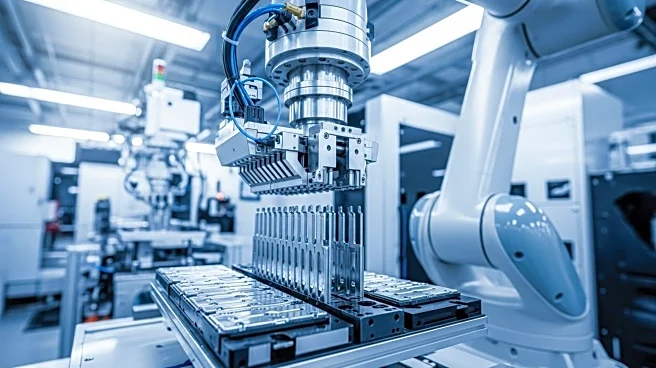

Kodak and Ateios Systems have announced a breakthrough in battery manufacturing, achieving a production speed of 80 meters per minute for solvent-free high-energy electrodes using the RaiCure platform. This speed is nearly three times faster than the industry standard, enabling high-voltage stability and thick coatings for various battery materials. The innovation promises lower costs, near-zero toxic emissions, and the elimination of forever chemicals. Ateios has secured multiple purchase orders and is shipping electrodes to battery OEMs in Asia and North America. The development is supported by a $350,000 grant from the NSF Energy Storage Engine.

Why It's Important?

This advancement in battery electrode production by Kodak and Ateios Systems represents a significant leap in sustainable manufacturing practices. The ability to produce high-energy electrodes at unprecedented speeds without harmful chemicals addresses critical environmental and efficiency challenges in the battery industry. This innovation could lead to cost reductions and improved performance in applications such as electric vehicles, grid storage, and consumer electronics. The collaboration highlights the potential for scalable and sustainable growth in the battery sector, aligning with global efforts to reduce carbon footprints and enhance energy storage solutions.

What's Next?

Kodak and Ateios Systems plan to expand their production capabilities, with Kodak's pilot line supporting widths up to 440 mm and full-scale production handling widths of up to 1.5 m. This expansion could lead to increased electrode capacity and further integration into various industries. The companies aim to take new battery designs from concept to commercial-scale production within months, potentially transforming the battery manufacturing landscape. Stakeholders in the electric vehicle and energy storage sectors will likely watch these developments closely, as they promise faster, more efficient, and environmentally friendly solutions.