What's Happening?

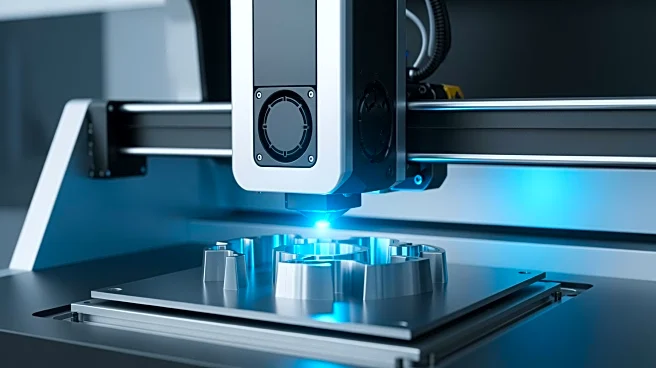

A new method for three-dimensional printing of thermoset materials has been developed, which is significant for the advancement of flexible electronics and soft robotics. Traditionally, the process of 3D printing thermoset materials involves the use of supporting

materials that require extensive pre- and post-processing. The new approach integrates in situ laser-induced solidification with direct ink writing, allowing for the construction of functional and arbitrary free-standing thermoset structures without the need for supporting materials. During the printing process, a laser is focused on a micro-sized polymer jet, leading to thermoset crosslinking in less than 0.25 seconds through a strong photothermal effect. This method offers a resolution as fine as 50 micrometers, with mechanical properties tunable by up to tenfold and electrical properties by up to 20-fold. The technique has been used to print stretchable electronics with stiffness gradients for strain inhibition, flexible sensors with high sensitivity, and three-dimensional soft magnetic robots for actuation functions.

Why It's Important?

The development of this laser-assisted 3D printing method is poised to significantly impact the fields of flexible electronics and soft robotics. By eliminating the need for supporting materials, the process reduces the complexity and cost associated with traditional 3D printing methods. This innovation allows for the creation of more sophisticated and functional devices, such as stretchable electronics and flexible sensors, which are crucial for advancements in wearable technology and robotics. The ability to fine-tune mechanical and electrical properties enhances the versatility and application range of printed devices, potentially leading to breakthroughs in various industries, including healthcare, automotive, and consumer electronics.

What's Next?

The adoption of this laser-assisted 3D printing technology could lead to increased research and development in the field of thermoset materials, encouraging further innovation and application. Industries that rely on flexible electronics and robotics may begin to integrate this technology into their manufacturing processes, potentially leading to new product developments and enhancements. As the technology becomes more widespread, it may also prompt regulatory bodies to establish new standards and guidelines for the use of laser-assisted 3D printing in commercial applications.

Beyond the Headlines

This advancement in 3D printing technology may also have ethical and environmental implications. The reduction in material waste and energy consumption associated with the elimination of supporting materials aligns with sustainable manufacturing practices. Additionally, the ability to produce complex devices with enhanced functionality could raise questions about intellectual property rights and the potential for misuse in areas such as surveillance and data collection.