What's Happening?

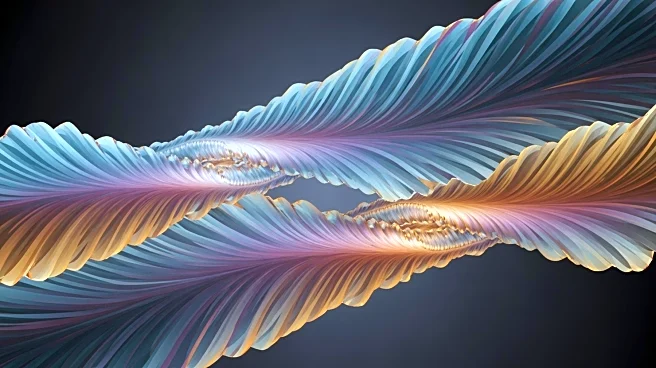

Researchers have demonstrated the ability to achieve chiral thermal emission using twisted bilayers of α-MoO3. This material exhibits strong in-plane optical anisotropy, making it suitable for creating

chiral light emitters. The study involved designing a heterostructure with two in-plane anisotropic materials on a reflective substrate, where the bottom layer acts as a lossy dichroic emitter and the top layer as a lossless quarter-wave plate. By twisting these layers, the system can emit circularly polarized light, achieving high circular dichroism (CD) values. The research confirms that α-MoO3's anisotropy, arising from its orthorhombic crystal structure, enables this chiral response.

Why It's Important?

This development has significant implications for optical technologies, particularly in enhancing the performance of devices that rely on polarized light. The ability to control the polarization state of emitted light could lead to advancements in areas such as thermal imaging, optical communication, and sensor technologies. The use of α-MoO3, a material with strong in-plane anisotropy, opens new possibilities for designing compact and efficient optical devices. This research also contributes to the broader understanding of how material properties can be engineered to achieve desired optical outcomes.

What's Next?

Future research may explore the integration of these chiral emitters into practical devices, assessing their performance in real-world applications. There is also potential for investigating other materials with similar anisotropic properties to expand the range of available chiral emitters. Additionally, the study of twisted bilayers could lead to new insights into the fundamental interactions between light and matter, informing the design of next-generation optical materials.

Beyond the Headlines

The findings highlight the importance of material science in advancing optical technologies. The ability to engineer materials at the nanoscale to achieve specific optical properties underscores the potential for innovation in this field. However, the scalability and cost-effectiveness of producing these materials for commercial applications remain challenges that need to be addressed.