What's Happening?

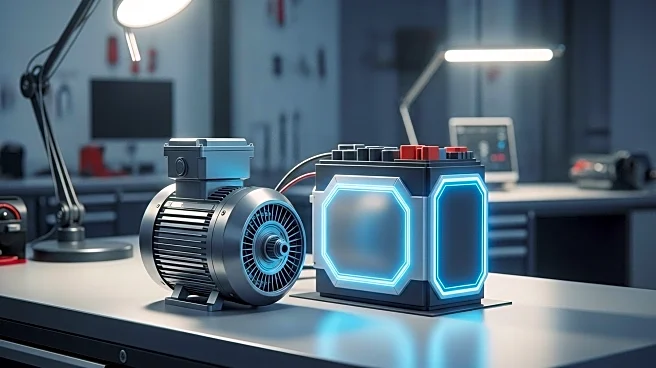

ZAPI Group is focusing on the development of next-generation powertrains for automated guided vehicles (AGVs) and automated mobile robots (AMRs) to improve efficiency and sustainability in material handling. The company is exploring the integration of advanced powertrain systems that offer intelligent energy management, regenerative braking, and predictive maintenance capabilities. These advancements aim to optimize labor by reallocating workers to more complex tasks, while enhancing the performance and reliability of AGVs. The choice between fully integrated and modular powertrain systems is crucial, impacting energy efficiency, maintainability, and total cost of ownership.

Why It's Important?

The development of advanced AGV powertrains is significant for industries relying on automated material handling, as it promises increased efficiency and reduced operational costs. By integrating intelligent systems, companies can achieve better energy management and fleet optimization, leading to improved productivity and sustainability. This shift is crucial for OEMs and machine engineers who need to balance performance with cost-effectiveness. As industries move towards smarter solutions, those adopting integrated powertrain systems are likely to gain a competitive edge, benefiting from enhanced safety, reliability, and reduced downtime.

What's Next?

The market is expected to see a broader range of integrated powertrain solutions, catering to various vehicle classes and performance needs. OEMs and system designers are likely to focus on smart powertrain integration, preparing for the adoption of artificial intelligence solutions in AGVs. This evolution will enable more precise matching of application requirements, balancing efficiency, safety, and scalability. As the industry continues to favor integrated solutions, companies that adapt to these changes will be better positioned to capture market share and establish themselves as leaders in autonomous mobility.

Beyond the Headlines

The integration of advanced powertrain systems in AGVs not only enhances operational efficiency but also supports compliance with safety standards without requiring structural redesigns. This development could lead to long-term shifts in how industries approach automation, emphasizing the importance of intelligent system design over individual component performance. The focus on modular architectures may drive innovation in AGV platforms, facilitating efficient deployment and scalability across various applications.