What's Happening?

NASA has developed a revolutionary tire technology known as the Superelastic Tire, originally designed for lunar and Martian exploration, which is now being adapted for use on Earth. This tire, made from

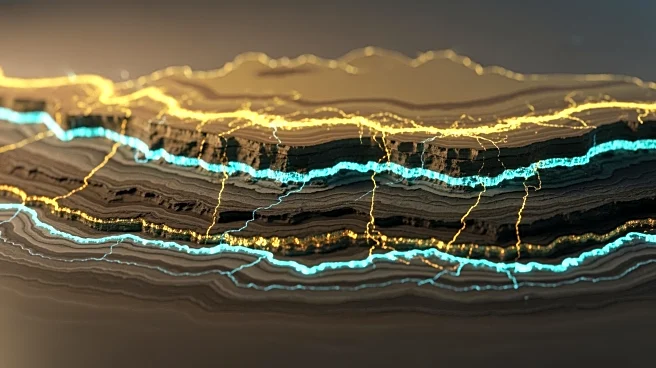

shape memory alloys, offers significant advantages over traditional rubber tires, including being airless, puncture-proof, and maintenance-free. The technology was initially created to withstand the harsh conditions of space, such as extreme temperatures and rough terrain, without the risk of punctures that could jeopardize missions. NASA's Glenn Research Center, in collaboration with Goodyear Tire and Rubber Company, engineered these tires using nickel-titanium alloys, which allow them to deform and return to their original shape without damage. The Superelastic Tire is now being licensed to commercial manufacturers for adaptation to consumer vehicles, potentially transforming the tire industry by eliminating the need for air pressure checks and reducing waste from discarded rubber tires.

Why It's Important?

The introduction of NASA's Superelastic Tire technology to consumer vehicles could significantly impact the automotive industry by reducing maintenance costs and environmental waste. Traditional rubber tires are prone to punctures and require regular air pressure checks, leading to frequent replacements and contributing to environmental pollution. The airless design of the Superelastic Tire eliminates these issues, offering a sustainable alternative that could extend the lifespan of tires and reduce the number of discarded tires. Additionally, the durability and performance consistency of these tires could enhance vehicle safety and efficiency, making them particularly appealing for electric and autonomous vehicles. As the automotive industry moves towards more sustainable practices, the adoption of this technology could play a crucial role in building cleaner and smarter transportation systems.

What's Next?

Before the Superelastic Tire can become a standard in commercial vehicles, several challenges need to be addressed. Scaling the technology for mass production is complex and costly, as nickel-titanium alloys are expensive to manufacture. Engineers are also working on ensuring that the metal tires provide a smooth and quiet ride at highway speeds, which is different from the behavior of rubber tires. Regulatory testing, road safety certification, and integration with existing vehicle systems are essential steps before these tires can reach consumers. Despite these hurdles, major manufacturers are showing interest, and efforts are underway to overcome these obstacles, paving the way for widespread adoption of this innovative technology.

Beyond the Headlines

The development of the Superelastic Tire represents a significant advancement in sustainable design, merging aerospace research with Earth-based needs. This innovation highlights how space technology can address everyday problems, offering a glimpse into the future of driving where maintenance-free and energy-efficient tires contribute to cleaner transportation systems. The potential for these tires to reduce environmental waste and improve vehicle safety aligns with global efforts to promote sustainability and reduce carbon footprints. As the technology progresses, it could lead to broader applications beyond personal vehicles, including bicycles and industrial machinery, further expanding its impact on modern mobility.