What's Happening?

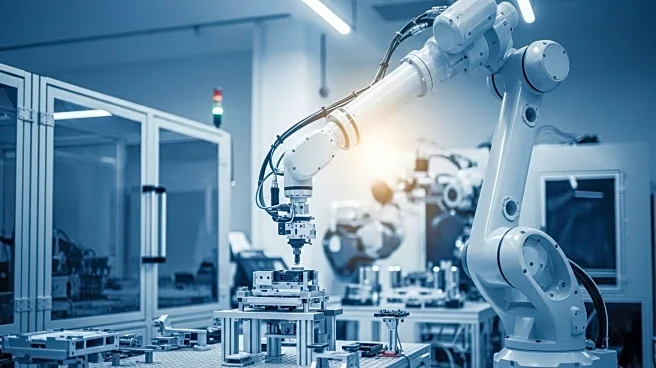

Stadler Anlagenbau, a manufacturer specializing in recycling and waste sorting systems, has integrated Panasonic Factory Solutions' Tawers G4 Welding Robot System into its production line. This advanced

system automates manual welding processes, significantly reducing cycle times and enhancing production efficiency. The G4 system features improved controller processing power, higher axis speeds, and optimized communication between the controller and robot, which collectively streamline the welding process. Additionally, the system's high-resolution touchscreen simplifies programming, while enhanced contact tips ensure superior welding quality and reliability. Stadler's adoption of this technology follows extensive simulations and test welds conducted at Panasonic's Robot & Welding Test Centre, with employees receiving specialized training to maximize the system's functionality.

Why It's Important?

The implementation of Panasonic's Tawers G4 Welding Robot System marks a significant advancement in Stadler's production capabilities, offering the potential for increased scalability and international expansion. By reducing cycle times to one-third of the original duration, Stadler can enhance throughput and efficiency, positioning itself to explore new business opportunities in electronic waste and clothing recycling. This technological upgrade not only improves operational reliability but also reduces maintenance downtime, providing Stadler with a competitive edge in the global market. The integration of Panasonic's DTPS software further supports Stadler's production line by enabling remote digital access to real-time data, facilitating virtual production planning and simulation, and optimizing manufacturing processes.

What's Next?

Stadler's adoption of the Tawers G4 Welding Robot System is expected to pave the way for its expansion into new regions and markets. The increased production efficiency and scalability provided by the system will allow Stadler to explore opportunities in electronic waste and clothing recycling, potentially leading to new partnerships and business ventures. Panasonic plans to showcase the Tawers G4 Welding Robot System at Schweisstec 2025, highlighting its capabilities to a broader audience and potentially attracting more industry interest in automated welding solutions.

Beyond the Headlines

The integration of advanced robotic systems like Panasonic's Tawers G4 represents a broader trend towards automation in manufacturing, which could have long-term implications for labor markets and production strategies. As companies increasingly adopt such technologies, there may be shifts in workforce requirements, with a growing emphasis on technical skills and training. Additionally, the enhanced efficiency and reliability of automated systems could lead to more sustainable manufacturing practices, reducing waste and resource consumption.