What is the story about?

What's Happening?

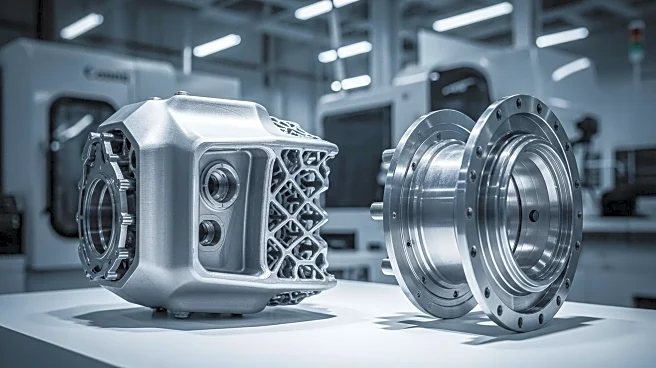

Titomic Ltd has announced a strategic partnership with Amaero Ltd to enhance its additive manufacturing capabilities. This collaboration focuses on securing a consistent supply of high-quality spherical refractory and titanium alloy powders for Titomic's cold spray additive manufacturing applications. The agreement aims to bolster Titomic's capabilities in coatings, repair, and near-net-shape part manufacturing, while establishing a resilient U.S. supply chain crucial for defense and aerospace sectors. The partnership aligns both companies' efforts to provide reliable and advanced material solutions, positioning Titomic to better support its customers in these critical markets.

Why It's Important?

The partnership between Titomic and Amaero is significant for the U.S. defense and aerospace industries, as it promises to enhance the supply chain resilience and manufacturing capabilities in these sectors. By securing a reliable source of advanced materials, Titomic can improve its production processes and offer better solutions to its clients, potentially leading to increased efficiency and reduced costs. This collaboration may also contribute to the technological advancement and competitiveness of U.S. defense and aerospace manufacturing, which are critical for national security and economic growth.

What's Next?

The strategic partnership is expected to lead to further developments in Titomic's manufacturing processes and product offerings. As the collaboration progresses, both companies may explore additional opportunities to expand their market presence and enhance their technological capabilities. Stakeholders in the defense and aerospace sectors will likely monitor the outcomes of this partnership closely, as it could influence future procurement decisions and industry standards.

Beyond the Headlines

This partnership highlights the growing importance of advanced manufacturing technologies in the defense and aerospace sectors. The use of cold spray additive manufacturing and high-quality alloy powders represents a shift towards more efficient and sustainable production methods. As these technologies become more prevalent, they may drive broader changes in manufacturing practices and supply chain management, potentially leading to increased innovation and competitiveness in the industry.