What's Happening?

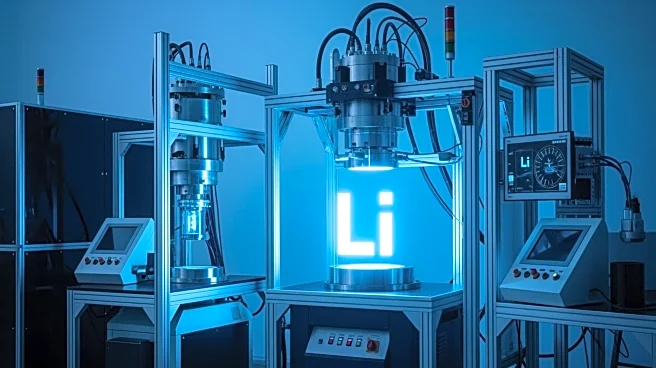

Cornish Lithium, a mining company based in Cornwall, has announced a significant achievement in the production of lithium hydroxide monohydrate (LHM). This development marks the first time LHM has been

produced in the UK, utilizing a repurposed china clay quarry and patented low-carbon processing technology. LHM is a crucial component in lithium-ion batteries, which are used in electric vehicles, grid-scale battery storage, and consumer electronics. The company's founder and executive chairman, Jeremy Wrathall, emphasized the importance of this milestone for both the company and the UK, highlighting the successful investment of £10 million into the project. Technical mining consultant James McFarlane praised the rapid progress from the company's founding in 2016 to achieving domestic production of LHM. Cornish Lithium plans to construct a full-scale lithium processing and refining plant, aiming for an annual capacity of up to 10,000 tonnes, potentially creating 300 jobs and injecting £800 million into the UK economy.

Why It's Important?

The production of lithium hydroxide monohydrate by Cornish Lithium represents a significant advancement for the UK's domestic supply chain of critical materials. As lithium-ion batteries are essential for the growing electric vehicle market and renewable energy storage solutions, securing a local source of LHM can reduce reliance on imports and enhance energy security. This development is poised to benefit the UK economy by creating jobs and fostering technological innovation in sustainable energy solutions. The investment in local production capabilities aligns with broader efforts to transition to cleaner energy and reduce carbon emissions, supporting the UK's environmental goals.

What's Next?

Cornish Lithium's plans to build a full-scale lithium processing and refining plant are expected to further bolster the UK's position in the global lithium market. The anticipated production capacity and economic impact suggest a positive outlook for job creation and industry growth. As the plant moves towards full-scale production by 2029, stakeholders in the automotive and renewable energy sectors may increasingly rely on domestic lithium supplies, potentially influencing market dynamics and investment strategies. Continued advancements in processing technology could also lead to further innovations in battery efficiency and sustainability.