What is the story about?

What's Happening?

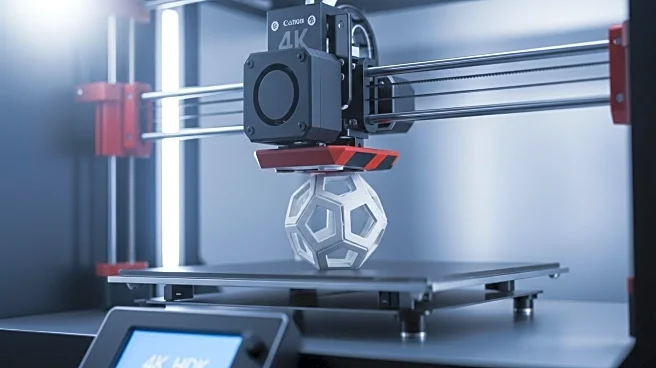

Craig Pyser, chairman of AMUK, has highlighted a significant knowledge gap in the UK defense sector regarding additive manufacturing. The Ministry of Defence's Advanced Manufacturing Strategy suggests that adopting additive manufacturing could save £110 million over 15 years. Despite the potential benefits, the defense sector's unfamiliarity with modern 3D printing applications is hindering these savings. Pyser emphasizes the need for education to bridge this gap and leverage existing UK capabilities in additive manufacturing.

Why It's Important?

The integration of additive manufacturing in defense could revolutionize supply chain resilience and reduce costs significantly. Bridging the knowledge gap could lead to substantial financial savings and enhance operational capabilities, particularly in areas like UAV and drone components. This shift could also stimulate economic growth in the manufacturing sector, driving innovation and competitiveness. The government's commitment to increasing defense spending further underscores the urgency of adopting advanced manufacturing technologies.

What's Next?

Efforts to educate decision-makers in the defense sector about modern additive manufacturing capabilities are crucial. As the Ministry of Defence shifts towards more flexible supply chain models, there is potential for increased adoption of 3D printing technologies. This could lead to strategic advantages and cost savings, encouraging further investment in the sector. Industry leaders may push for policy changes to support the integration of these technologies in defense manufacturing.