What's Happening?

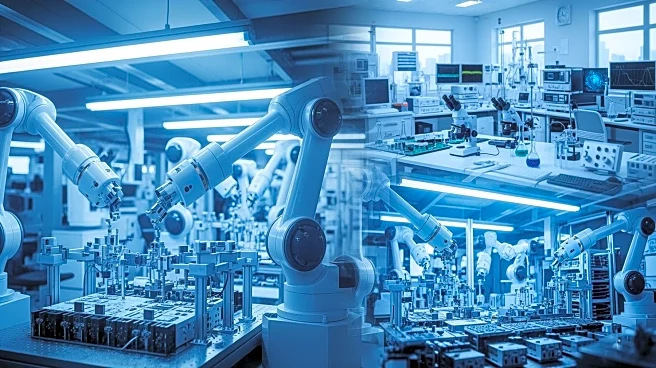

Delta Electronics, a Taiwan-based company specializing in power management and IoT solutions, is expanding its presence in India. The company has established 16 regional offices, three manufacturing facilities, and two R&D centers in the country. Delta Electronics is aligning

its operations with India's 'Make in India' and 'Digital India' initiatives by integrating advanced technologies like DIASECS and DIAEAP+ across its facilities. These platforms enhance connectivity, predictive maintenance, and automated workflows, helping Indian manufacturers achieve global standards in efficiency and quality.

Why It's Important?

Delta Electronics' expansion in India underscores the country's growing role as a hub for manufacturing and technological innovation. By investing in local infrastructure and aligning with national initiatives, Delta is contributing to India's economic growth and technological advancement. The company's focus on sustainability and digital transformation reflects broader industry trends towards energy efficiency and reduced carbon emissions. As Delta continues to invest in India, it may drive further development in sectors like EV charging, renewables, and data centers, potentially creating new opportunities for local businesses and workforce.

What's Next?

Delta Electronics plans to expand its R&D presence in India and increase its technology budget to support digital transformation and innovation. The company aims to leverage AI and analytics to enhance its manufacturing processes and customer outcomes. As Delta deepens its focus on automation and sustainability, it may influence industry standards and practices, particularly in areas like smart manufacturing and energy management.

Beyond the Headlines

Delta Electronics' commitment to sustainability and innovation may have long-term implications for the manufacturing industry, including shifts towards more energy-efficient and environmentally friendly practices. The company's efforts to integrate AI and digital twins into its operations could lead to advancements in predictive analytics and cybersecurity, shaping the future of smart manufacturing.