What is the story about?

What's Happening?

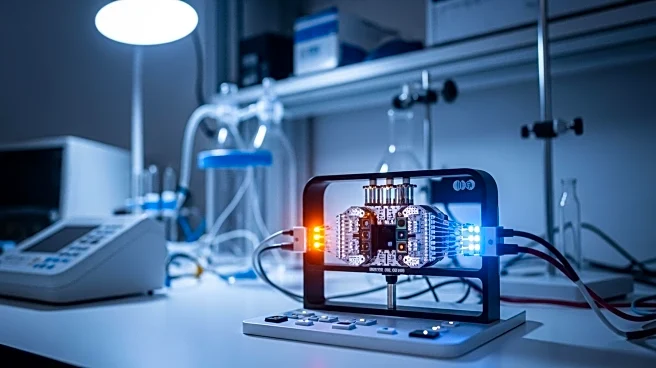

Researchers at the Terasaki Institute, led by Dr. Vadim Jucaud, have developed a microfluidic-based biosensing platform to monitor monoclonal antibody secretion in real time. This innovation aims to make antibody production more efficient and cost-effective, addressing the global demand for these biotherapeutics. The platform uses a microfluidic design to minimize culture volume and concentrate antibodies, enabling rapid characterization of antibody secretion. This technology allows for the selection of high-secreting clones, optimizing production methods and reducing costs, ultimately making immunotherapies more accessible to patients.

Why It's Important?

Monoclonal antibodies are crucial for treating a wide range of diseases, including cancer and autoimmune disorders. The ability to monitor antibody production in real time represents a significant advancement in biomanufacturing, potentially lowering costs and increasing accessibility to life-saving therapies. This platform exemplifies how biosensor technologies can revolutionize the production process, enhancing efficiency and precision. By identifying high-secreting cells early, manufacturers can improve scalability and reduce unnecessary expenses, benefiting both the industry and patients who rely on these treatments.

What's Next?

The platform's rapid and scalable design is expected to support both fundamental research and industrial-scale biomanufacturing. As the demand for antibody-based diagnostics and therapies continues to grow, this technology could play a pivotal role in meeting global needs. Further development and integration of this biosensing platform may lead to more streamlined production processes, expanding the availability of monoclonal antibodies. Researchers and manufacturers may explore additional applications of this technology, potentially leading to new innovations in the field of biotherapeutics.