What's Happening?

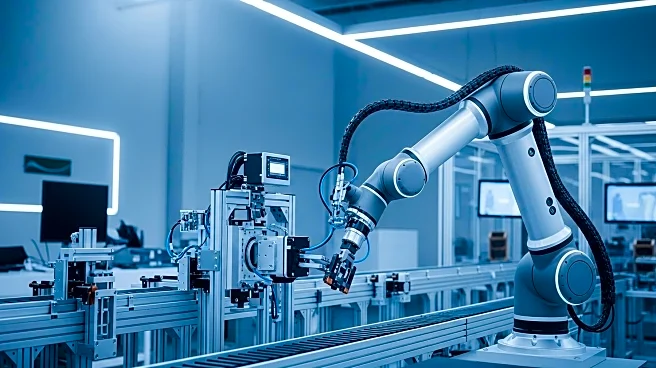

The integration of AI with lean manufacturing practices is being explored to enhance efficiency and quality in production processes. AI can analyze defect patterns, suggest design changes, and improve decision-making, aligning with lean principles of building quality at the source. Companies like Toyota and GE Appliances are using AI to accelerate plan-do-check-act cycles and improve flow and safety. The Lean Enterprise Institute has piloted AI experiments to raise coaching quality, demonstrating AI's potential as a thought partner in lean transformations.

Why It's Important?

The combination of AI and lean practices represents a significant shift in manufacturing, offering the potential to streamline operations, reduce waste, and improve product quality. By leveraging AI, companies can enhance their problem-solving capabilities, optimize resource allocation, and increase competitiveness. This integration supports the broader trend of digital transformation in manufacturing, which is crucial for maintaining global competitiveness and meeting evolving consumer demands. The approach also emphasizes the importance of human oversight and creativity, ensuring that technology complements rather than replaces human expertise.