What's Happening?

Walmart is reinforcing its commitment to U.S.-based manufacturing as part of its strategy to enhance supply chain flexibility. At its 12th annual Open Call event, Walmart invited over 500 entrepreneurs

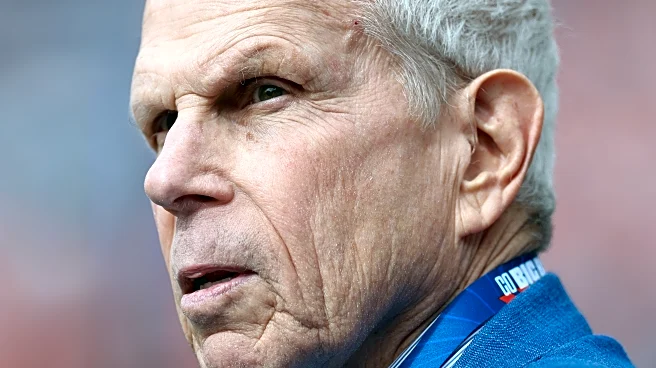

to pitch products made, grown, or assembled in the United States. This initiative is part of Walmart's $350 billion, 10-year commitment to domestic sourcing. John Furner, Walmart U.S. CEO, highlighted the benefits of investing in U.S. manufacturing, noting that it supports business growth, employment, and national economic strength. Recent projects include a beef-processing facility in Olathe, Kansas, expected to create approximately 600 jobs, and a partnership with USAntibiotics to restore local drug production. Walmart's approach combines economic nationalism with supply-chain flexibility, reshoring when it strengthens resilience while continuing to source globally for products better produced elsewhere.

Why It's Important?

Walmart's emphasis on U.S. manufacturing is significant for several reasons. It supports job creation and economic growth within the United States, providing a boost to local industries and communities. By reshoring production, Walmart can improve supply chain resilience, reduce lead times, and enhance quality control. The 'Made in the U.S.A.' label remains meaningful to American consumers, signaling reliability and accountability, which can strengthen brand authenticity and justify premium pricing. This strategy also allows Walmart to navigate tariffs more effectively, as domestic production can offset some of the cost increases associated with international trade barriers. Overall, Walmart's approach could serve as a model for other businesses seeking to balance domestic and global sourcing to optimize their supply chains.

What's Next?

Walmart's continued investment in U.S. manufacturing is likely to influence other major retailers and manufacturers to consider similar strategies. As the company develops new facilities and partnerships, it may further enhance its supply chain flexibility and resilience. The success of these initiatives could lead to increased domestic production across various industries, potentially reshaping the U.S. manufacturing landscape. Additionally, Walmart's approach may prompt discussions among policymakers and industry leaders about the benefits of reshoring and its role in strengthening the national economy. Stakeholders will be watching closely to see how these developments impact employment, consumer prices, and the overall competitiveness of U.S. businesses in the global market.

Beyond the Headlines

Walmart's reshoring efforts highlight broader ethical and cultural dimensions, such as the importance of supporting local economies and sustainable practices. By prioritizing domestic production, Walmart is contributing to a shift towards more responsible and transparent supply chains. This move may encourage other companies to adopt similar practices, fostering a culture of accountability and sustainability in manufacturing. Additionally, the focus on U.S. manufacturing could lead to long-term shifts in consumer preferences, with more Americans seeking products that are locally sourced and produced. This trend could drive innovation in domestic industries, as companies strive to meet the evolving demands of consumers who value quality, authenticity, and environmental responsibility.