What's Happening?

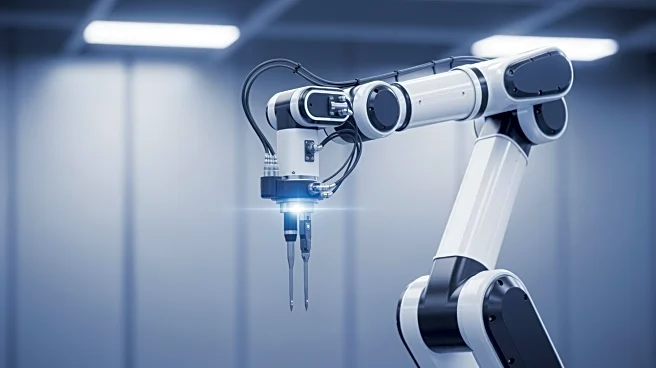

Epson Robots, known for its precision automation solutions, is addressing the growing demand for easy-to-deploy robotic systems. The company has a strong market position in the SCARA robot segment and offers

compact six-axis systems, vision tools, and integrated software environments. Labor shortages and reshoring efforts are driving small and mid-sized manufacturers to seek automation solutions that do not require large specialist teams. Epson's approach includes simplifying deployment with integrated vision and feeding capabilities, and easy-to-program robots that can handle various tasks in tight spaces.

Why It's Important?

Epson's focus on simplifying robotic deployment is crucial as manufacturers face persistent labor shortages and increasing production demands. By lowering the skills barrier, Epson enables companies to adopt automation more easily, enhancing business performance and time-to-market. This approach is particularly beneficial for industries such as electronics, medical devices, and consumer goods, where precision and repeatability are essential. Epson's solutions could lead to broader adoption of robotics, driving efficiency and competitiveness in the manufacturing sector.

What's Next?

Epson is expected to continue expanding its product offerings and simplifying integration processes to meet the evolving needs of manufacturers. The company may focus on developing more compact and integrated solutions, enhancing its market position and addressing the demand for flexible automation. As technology advances, Epson's approach could influence the next phase of robotics growth, with more manufacturers adopting its model to scale intelligently without adding complexity.

Beyond the Headlines

Epson's strategy aligns with broader trends in robotics adoption, such as the need for modularity and quick reconfiguration. The company's focus on accessibility and ease of use may drive long-term changes in how manufacturers approach automation, potentially leading to more sustainable and efficient production processes.