What's Happening?

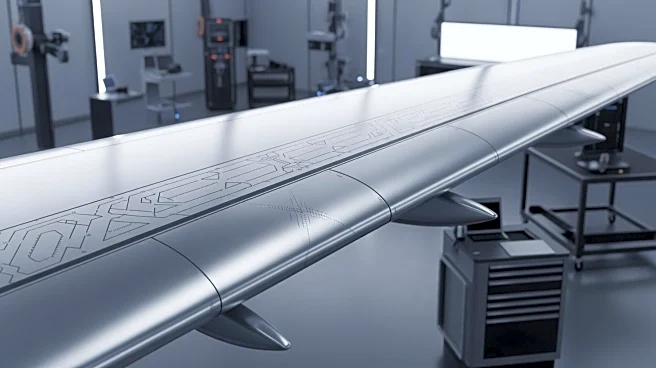

Researchers at the University of Alabama, led by Professor Samit Roy, are developing self-healing aircraft materials that can detect and repair structural damage in real-time. These materials, embedded

with sensors, act like a nervous system, continuously monitoring stress and strain. When damage occurs, the sensors trigger a healing response, restoring structural integrity without human intervention. The technology, still in the testing phase, uses carbon fiber-epoxy composites enhanced with shape-memory polymers and thermoplastic powders. Initial funding from the US Air Force has supported the development of prototypes, with potential applications in commercial aviation, space exploration, and military operations.

Why It's Important?

Self-healing materials could revolutionize aviation safety by allowing aircraft to repair themselves mid-flight, reducing the risk of catastrophic failures. This technology could extend the lifespan of airframes, decrease maintenance costs, and minimize downtime. In space exploration and combat zones, where repairs are challenging, self-healing materials could be life-saving. The integration of artificial intelligence and digital twin technology further enhances the system's ability to predict and respond to structural stress, aligning with NASA's vision for autonomous sensing and repair in aerospace design.

What's Next?

The technology remains in the testing phase, with challenges in scaling to full airframes, including cost, manufacturability, and certification. However, industry interest is growing, particularly among airlines and defense agencies seeking to extend fleet life and reduce downtime. Continued research and development efforts are expected to refine the system for full-scale applications, potentially leading to commercial adoption in the future.

Beyond the Headlines

The development of self-healing materials represents a significant shift towards resilience in aerospace design, where machines not only withstand stress but recover from it. This evolution brings aviation closer to biological systems, where structures can feel, react, and respond. The technology also serves as a living classroom for innovation, providing students with hands-on experience in advanced research and real-world aerospace challenges.