What's Happening?

Researchers at the Ecole Polytechnique Fédérale de Lausanne (EPFL) in Switzerland have developed a new method to create 3D-printed metal structures that are 20 times stronger than those produced by traditional

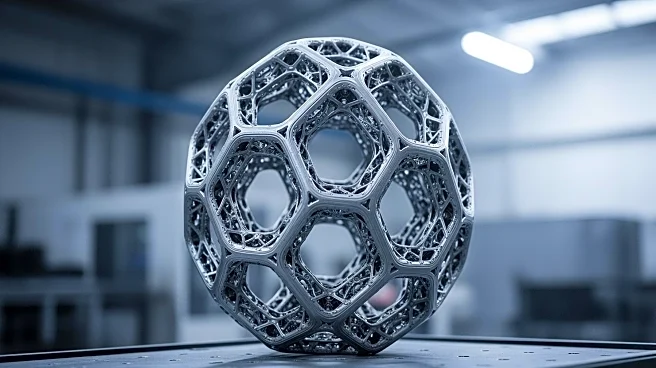

methods. This breakthrough involves using vat photopolymerization, a process that typically utilizes light-reactive resin to form intricate structures. The scientists first 3D-printed a lattice made of hydrogel, which was then soaked in metal salts. This allowed metal-containing nanoparticles to spread throughout the structure. After repeating this process multiple times, the hydrogel was removed through heating, leaving behind a dense metallic structure. This method not only enhances the strength of the metal but also significantly reduces shrinkage, a common issue with traditional vat photopolymerization techniques.

Why It's Important?

The development of stronger 3D-printed metal structures has significant implications for industries that rely on complex components, such as electrical batteries and storage technologies. By overcoming the limitations of traditional vat photopolymerization, this method could lead to more durable and reliable products. The ability to fabricate high-quality metals and ceramics using a low-cost 3D printing process could revolutionize manufacturing, making it more accessible and efficient. However, the process is currently time-consuming, which may hinder its immediate adoption by industries. Efforts are underway to automate the steps involved, potentially reducing the processing time and making the technology more appealing to manufacturers.

What's Next?

The research team is working on automating the infusion steps to reduce the overall processing time required to create these 'grown' metal structures. This automation could make the method more viable for industrial applications, where time efficiency is crucial. As the technology advances, it may lead to broader adoption in various sectors, potentially transforming manufacturing processes and enabling the production of more complex and durable components. The ongoing research and development efforts aim to address the current challenges and pave the way for widespread use of this innovative 3D printing technique.

Beyond the Headlines

This advancement in 3D printing technology highlights a shift in additive manufacturing, where material selection occurs after the printing process rather than before. This paradigm shift could lead to new possibilities in material science, allowing for the creation of customized materials with specific properties tailored to different applications. The ethical and environmental implications of this technology are also worth considering, as it may reduce waste and resource consumption by enabling more efficient manufacturing processes.