What's Happening?

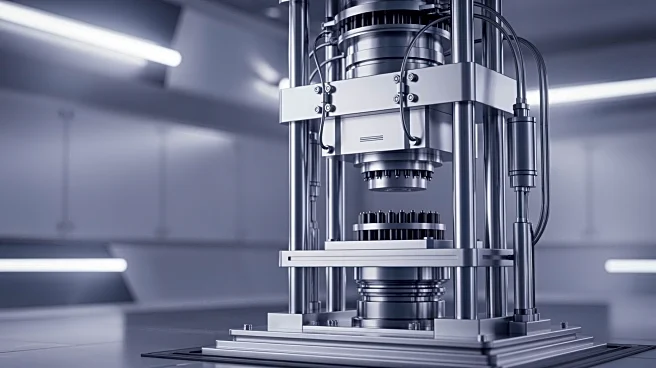

Rhodes Interform, a division of Group Rhodes, has been awarded a significant contract to design and manufacture three bespoke hydraulic presses for the aerospace industry. The contract involves the production

of two 180-tonne presses and one 500-tonne press, which will be used to bond multi-layered composite sheets into single composite components. These four-column, hot platen presses are equipped with advanced features such as integrated structure cooling, fume extraction, and precise control over speed, tonnage, and temperature. The presses are designed and manufactured in Wakefield, West Yorkshire, with testing conducted both at the factory and the customer's premises. This project highlights Rhodes Interform's expertise in creating specialized machinery for composite and metal forming applications.

Why It's Important?

This contract underscores Rhodes Interform's pivotal role in the aerospace sector, particularly in the production of lightweight aero structures. The company's advanced technology, including its patented Superplastic Forming and Diffusion Bonding methods, is crucial for manufacturing large, complex parts that are essential for modern aerospace and automotive industries. The ability to produce bespoke machinery tailored to specific client needs enhances the company's reputation and competitiveness in the global market. This development also reflects the ongoing demand for innovative solutions in the aerospace industry, which is increasingly focused on efficiency and sustainability.

What's Next?

Following the successful completion of this contract, Rhodes Interform may see increased demand for its specialized machinery in other sectors requiring lightweight and complex component manufacturing. The company's continued innovation and patent acquisitions could lead to further expansion in international markets, particularly in regions where aerospace and automotive industries are rapidly growing. Additionally, the successful execution of this project may lead to more collaborative opportunities with aerospace companies seeking customized solutions for their manufacturing processes.

Beyond the Headlines

The contract highlights the importance of innovation in manufacturing technology, particularly in sectors like aerospace where precision and efficiency are paramount. Rhodes Interform's ability to recondition and upgrade existing machinery also offers a sustainable alternative to purchasing new equipment, aligning with broader industry trends towards sustainability and cost-effectiveness. This approach not only reduces waste but also extends the lifecycle of machinery, providing economic and environmental benefits.