What's Happening?

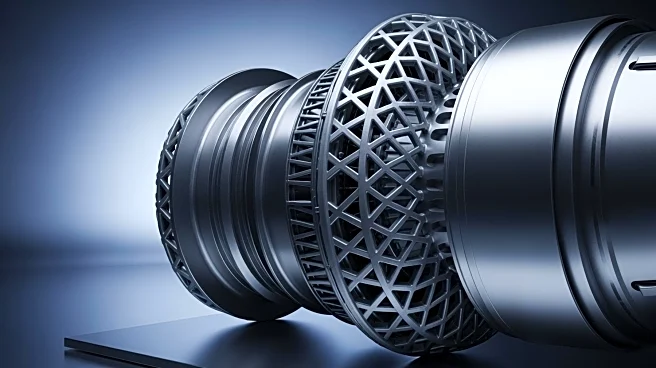

China has successfully conducted the first flight of a domestically developed 3D-printed turbojet engine, marking a significant advancement in aerospace technology. The engine, developed by the Hunan Aviation Powerplant Research Institute, a subsidiary

of Aero Engine Corporation of China (AECC), was tested on the Liuxing-260 technology demonstrator drone. The flight took place in November 2025, with the aircraft reaching an altitude of 6,000 meters and a top speed of Mach 0.75 during a 30-minute flight. The engine, weighing 160 kilograms, was produced with approximately 60% of its components using additive manufacturing techniques, which allowed for a reduction in the number of parts by about 60%. This innovation aims to lower production costs and enhance system reliability. The successful integration of the engine with the drone demonstrates its readiness for operational use in uncrewed aircraft systems and cruise missiles.

Why It's Important?

The successful test of China's 3D-printed turbojet engine represents a major step forward in the aerospace industry, particularly in the realm of cost-effective and efficient production methods. By utilizing 3D printing technology, the production process can be streamlined, reducing the number of parts and potentially lowering manufacturing costs. This development could have significant implications for the global aerospace market, as it may lead to more affordable and reliable jet engines. Additionally, the ability to produce complex geometries through additive manufacturing could enhance the performance and versatility of aerospace components. The advancement also highlights China's growing capabilities in aerospace technology, which could influence global competition in the sector. The successful test flight suggests that China is moving closer to commercializing this technology, which could impact the market for uncrewed aircraft and missile systems.

What's Next?

Following the successful test flight, the next phase for China's 3D-printed turbojet engine involves testing across a broader range of platforms and operating environments. The goal is to advance the design towards commercialization, which would involve further refinement and validation of the engine's performance and reliability. This process will likely include additional flight tests and integration with various uncrewed aircraft systems and cruise missiles. As the technology progresses, it may attract interest from international aerospace companies and defense contractors looking to incorporate cost-effective propulsion systems into their products. The development could also prompt other countries to invest in similar technologies to remain competitive in the aerospace industry.