What's Happening?

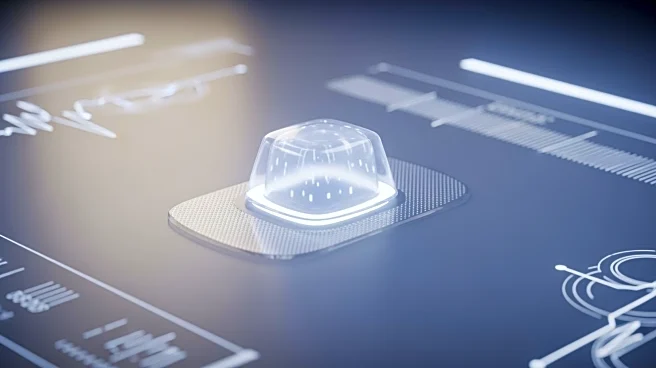

Researchers from Guangdong Technion-Israel Institute of Technology, Technion-Israel Institute of Technology, Shantou University Medical College, and the University of Tokyo have developed a new type of hydrogel

that remains hydrated and functional over extended periods. This hydrogel is created by dip-coating polyurethane nanomeshes into a gelatin hydrogel solution, which solidifies at physiological temperatures. The resulting material is both thin and mechanically robust, offering a stretchability of 238% strain and a water vapor permeability of 1,252 g m−2 day−1. To enhance its durability, a water-glycerol binary solvent and lithium chloride are added, reducing water loss to just 2% after 12 days. This innovation also improves the hydrogel's anti-freezing properties, making it suitable for use in extreme environments. The hydrogel electrodes have been successfully used for continuous electrocardiogram (ECG) monitoring over eight consecutive days.

Why It's Important?

The development of this hydrogel is significant for the medical field, particularly in patient monitoring. Traditional hydrogels often dry out, limiting their use in long-term applications. This new hydrogel's ability to maintain hydration and functionality over extended periods could revolutionize continuous patient monitoring, reducing the need for frequent electrode changes and improving patient comfort. The enhanced anti-freezing properties also expand its potential applications in various environmental conditions, making it a versatile tool for healthcare providers. This could lead to more reliable and efficient monitoring systems, ultimately improving patient outcomes and reducing healthcare costs.

What's Next?

The next steps for this hydrogel technology could involve further testing and refinement to ensure its efficacy and safety in diverse clinical settings. Researchers may explore additional applications beyond ECG monitoring, such as in other types of biosensors or wearable health devices. Collaboration with medical device manufacturers could facilitate the integration of this hydrogel into commercial products, potentially leading to widespread adoption in healthcare facilities. Regulatory approval processes will also be a critical step before the hydrogel can be used in clinical practice.

Beyond the Headlines

This development may also have implications for the broader field of materials science, particularly in the design of hydrogels with enhanced properties for various industrial applications. The incorporation of a water-glycerol binary solvent and lithium chloride to prevent drying and improve anti-freezing properties could inspire similar innovations in other materials. Additionally, the environmental impact of producing and disposing of traditional hydrogels could be mitigated by this more durable alternative, contributing to more sustainable practices in both healthcare and materials manufacturing.