What's Happening?

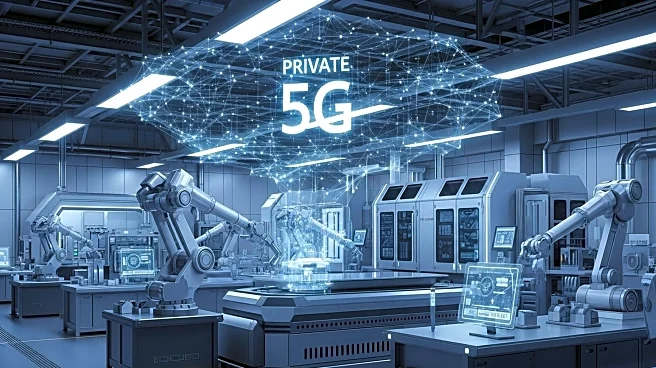

NTT Data has installed a managed private 5G network from Celona at two Celanese manufacturing plants in Texas, aiming to improve connectivity for worker safety and automation. The deployment covers large outdoor production facilities with complex operating requirements. Celanese, a Fortune 500 company headquartered in Irving, Texas, is a leading producer of acetic acid and vinyl acetate monomer. The private 5G network is expected to support connected workers, automation, and IoT applications, overcoming coverage challenges at large sites. NTT Data plans to expand the network to other Celanese sites globally, exploring new use cases for manufacturing and industrial efficiency.

Why It's Important?

The deployment of private 5G networks at Celanese plants represents a significant advancement in industrial connectivity, enhancing operational efficiency and worker safety. By enabling real-time decision-making and automation, the network supports Celanese's focus on innovation and operational excellence. This move is crucial for the chemical industry, which requires secure, high-speed connectivity to maintain uninterrupted logistics and production lines. The initiative also highlights the growing trend of integrating advanced technologies in manufacturing to improve productivity and competitiveness.

What's Next?

NTT Data and Celanese are exploring additional IoT use cases to further enhance manufacturing processes. The potential expansion of the private 5G network to other Celanese sites globally could lead to broader adoption of advanced connectivity solutions in the chemical industry. Stakeholders, including industry leaders and policymakers, may respond by investing in similar technologies to boost industrial efficiency and competitiveness.

Beyond the Headlines

The deployment of private 5G networks in manufacturing settings raises questions about data security and privacy. As companies increasingly rely on connected technologies, ensuring robust cybersecurity measures will be essential to protect sensitive information and maintain operational integrity. Additionally, the integration of IoT and automation technologies may lead to shifts in workforce dynamics, requiring new skills and training for employees.