What's Happening?

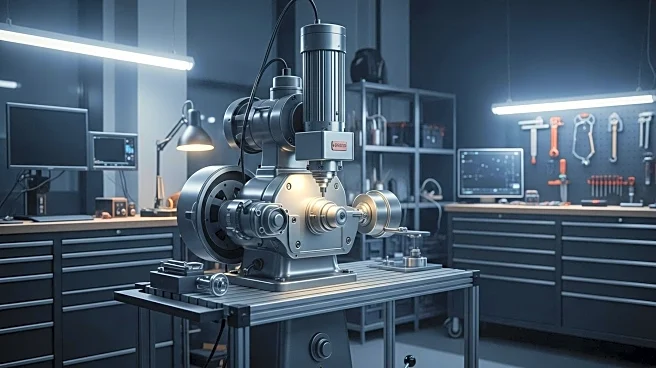

BEP Surface Technologies, a specialist in electroplating and surface finishing, is undertaking a major refurbishment project to upgrade a 70-year-old Churchill TWR roll grinder. The project, valued at over $805,000, involves a complete mechanical and electrical overhaul in collaboration with Siemens and Made Smarter. The upgrade aims to achieve ultra-precise finishes for sectors like electric vehicle batteries and carbon fiber manufacturing. The project is currently 30% complete and is expected to significantly enhance BEP's production capabilities.

Why It's Important?

This refurbishment project is crucial for BEP Surface Technologies as it seeks to expand its capabilities and meet the growing demand for precision engineering in high-growth sectors. By achieving tighter tolerances, the company can secure new business opportunities and reduce reliance on European suppliers, thereby strengthening the UK supply chain. The project also underscores the importance of digital technology in modernizing manufacturing processes and maintaining competitive advantage in a global market.

What's Next?

As the project progresses, BEP Surface Technologies will continue to integrate advanced digital controls and provide training to its workforce. The completion of this project is expected to open new business avenues and enhance the company's ability to compete globally. The successful implementation of this technology could serve as a model for other manufacturing firms looking to modernize their operations.