What is the story about?

What's Happening?

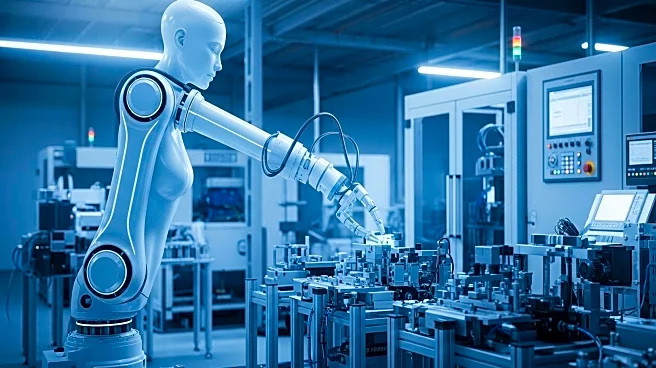

The rapid advancement of humanoid robots is raising questions about their role in manufacturing environments such as industrial factories, semiconductor fabs, and pharmaceutical labs. Tyler Bouchard, CEO of Flexxbotics, emphasizes the need for humanoids to be coordinated and orchestrated within smart factories to achieve true autonomy. This involves humanoids performing multiple operations autonomously alongside other robots and plant assets for lights-out production. Bouchard highlights the importance of humanoids operating with context, requiring them to communicate with other robots, machines, and IT business systems throughout the plant. This communication is essential for humanoids to receive instructions on product building, process running, and work execution, as well as to send updates back to business systems to keep records current.

Why It's Important?

The integration of humanoid robots into manufacturing processes has the potential to revolutionize production by enabling autonomous operations and reducing reliance on human intervention. This could lead to increased efficiency, reduced labor costs, and enhanced productivity in manufacturing sectors. The ability of humanoids to communicate and coordinate with existing factory equipment and systems is crucial for achieving these benefits. Successful implementation of humanoid orchestration could position companies like Flexxbotics at the forefront of robot-driven manufacturing, offering competitive advantages in terms of innovation and operational efficiency. However, achieving this level of autonomy requires significant advancements in robotic production software and interoperable communication systems.

What's Next?

The development of humanoid robots capable of autonomous operation in manufacturing environments is likely to continue, with companies investing in robotic production software to facilitate communication and coordination. Industry events such as RoboBusiness 2025, which includes sessions on humanoids, physical AI, and enabling technologies, provide platforms for stakeholders to discuss and explore advancements in this field. As humanoids become more integrated into manufacturing processes, companies may need to adapt their business models and strategies to leverage the benefits of robot-driven production. This could involve re-evaluating workforce roles, investing in new technologies, and developing partnerships to enhance robotic capabilities.

Beyond the Headlines

The orchestration of humanoid robots in manufacturing raises ethical and cultural considerations, particularly regarding the displacement of human workers and the need for reskilling. As robots take on more complex tasks, there may be concerns about job security and the changing nature of work. Additionally, the reliance on advanced communication systems and software for robot autonomy highlights the importance of cybersecurity and data protection in manufacturing environments. Long-term shifts could include increased collaboration between humans and robots, leading to new forms of work and production processes.