What is the story about?

What's Happening?

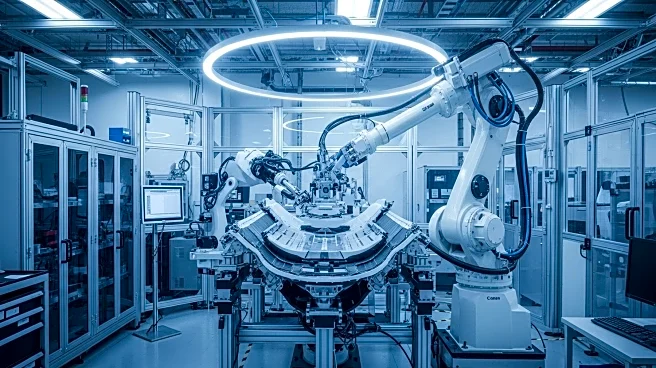

CT UAV has introduced a groundbreaking self-evolving composite molding plant, known as the NAACP-class Composite plant, which focuses on advanced aerospace manufacturing. This facility is designed to produce fuselages, wings, and other aircraft parts using cutting-edge materials like Kevlar and Zylon fibers. The plant integrates state-of-the-art technologies such as automated AFP/ATL systems, multi-axis robot lay-up, and AI-driven quality control processes. These innovations aim to enhance precision, reduce production costs, and improve the strength-to-weight ratio of aerospace components.

Why It's Important?

The establishment of CT UAV's composite molding plant represents a significant advancement in aerospace manufacturing technology. By leveraging automation and AI, the plant is poised to increase production efficiency and reduce costs, potentially transforming the aerospace industry. This development could lead to more competitive pricing for UAVs and other aerospace products, benefiting manufacturers and consumers. Additionally, the plant's focus on sustainability and advanced materials aligns with global trends towards greener and more efficient manufacturing processes.

What's Next?

CT UAV is expected to continue refining its manufacturing processes and expanding its capabilities in aerospace technology. The plant's innovations may attract interest from military and commercial aerospace sectors, leading to potential collaborations and contracts. As the plant evolves, CT UAV may explore further applications of its technologies in other industries, such as automotive or renewable energy.