What's Happening?

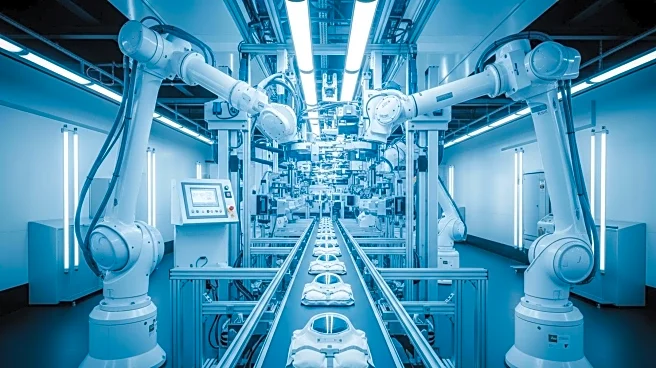

The COVID-19 pandemic exposed vulnerabilities in global supply chains, particularly for essential medical equipment like PPE. In response, a new U.S.-based PPE business was launched, focusing on domestic production to ensure reliable access to critical items such as masks, gloves, gowns, and hairnets. Wauseon Machine, an automation solutions provider, developed a novel thermoplastic welding process to automate hairnet production, overcoming challenges associated with manual labor and stitching. This innovation allows for efficient production of sewn-style hairnets, meeting the needs of healthcare providers.

Why It's Important?

The shift to domestic PPE production is crucial for enhancing supply chain resilience and reducing dependency on international sources. By developing innovative manufacturing processes, companies like Wauseon Machine contribute to national security and healthcare preparedness. This move supports U.S. industries by creating jobs and fostering technological advancements. It also ensures that healthcare providers have consistent access to essential equipment, which is vital for patient care and safety.

What's Next?

The success of domestic PPE production could serve as a model for reshoring other critical manufacturing sectors, such as defense and aerospace. As demand for PPE remains high, continued innovation and investment in automation technologies will be necessary to meet production goals and maintain quality standards. Stakeholders may explore further partnerships and government support to expand domestic manufacturing capabilities.